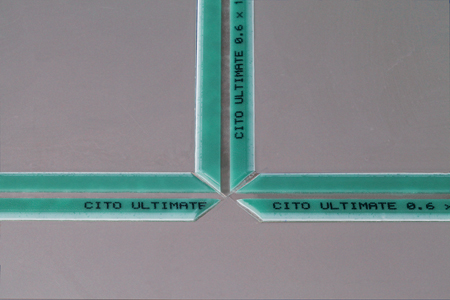

Cito used drupa to promote its ‘Ultimate’, a special flexible surface coating that enables extremely large runs. Indeed, runs of up to 480,000 sheets have already been achieved in the processing of folding carton board using Cito Ultimate. Since such run sizes are extremely rare in Europe, these results were obtained through several runs within an order. The cutting tool was left in the chase, to avoid any impact from tool changing. To enable precise insertion of the cutting plate, a measurement was made using the Cito Creasy system. The key feature of ‘Ultimate’ creasing system is the consistently high quality of the creasing profile. Measurement of the cuts found a minimal deviation in the profile characteristics of first die-cut sheet compared with sheet number 480,000 – the deviation was of the order of less than 0.03mm.

Based on the success with folding carton board, Cito has decided to expand its product spectrum by the end of the year to cover micro flute and corrugated board. The most important factor here is not so much the possible run size but the highly consistent crease quality. The blanks processed with ‘Ultimate’ are discernibly less susceptible to disturbances when subjected to further processing, which results in both increased efficiency and in turn a reduction in costs.

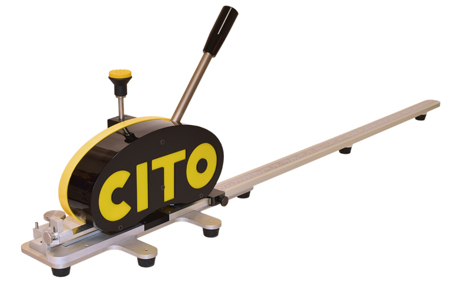

The perfect combination comprises ‘Ultimate’ used in conjunction with the new Cito AC 3 Cutter. This new cutting technology, which automatically chamfers the creasing matrices on the cut edges, requires virtually no additional working on the cutting plate. European customers have confirmed that creasing matrices cut with the AC 3 Cutter could be used immediately and without any further handling. Initial calculations for customers in Germany found the cost saving to be of the order of €40,000 to € 50,000 per year. These calculations were based on four to five makeready operations per day and an average cutting die yield of six to eight. Naturally, Cito creasing systems can also be processed with this cutting technology.

“A number of folding carton producers are already considering working with Cito Ultimate rather than Pertinax matrices, because in many cases, the AC 3 Cutter incurs minimal additional handling, which is more than made up for by the consistent crease quality,” says Jürgen Mariën, CEO of the Cito Group. “I have been dealing with the subject of creasing technology for nearly 35 years and I have seen the adoption of a number of great developments in practice. Our new system is the result of years of development activity and it naturally gives me great pleasure that we have achieved such great success with it. It is just wonderful to realise how our development team’s work is appreciated by our customers all over the world.”