“The summer has not ended yet and an innovative and inspiring industry is up and ready for the next challenge,” says Ulrich Wolz, COO of Bahmüller. Just three weeks ahead of Fachpack 2016 in Nuremberg, Bahmüller held its annual open house in Plüderhausen, Germany recently. Some intriguing machines were on the show and the Bahmüller team was keen to present the milestone features to the audience.

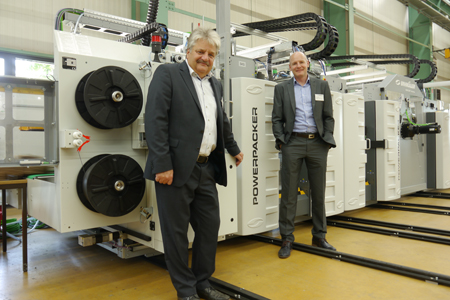

Turbox is in its tenth year and Powerpacker #25 was on display, as well as the new generation of Powerpacker banding system.

Supported by a team of partners (including ATS Tanner, Baumer HHS, Eukalin and SMB with its SMBCOR semi automatic bundling machine), almost the entire process of speciality folder gluing was shown. More than 100 companies sent their representatives from all over Europe and got together over three days. The Bahmüller process engineers — Thomas Wossog, Mike Barron, Rudi Glätsch and Ottmar Praher — made the event a great success by showing the possibilities of Turbox and Powerpacker in full speed operation. Visitors saw set-up and run speed, together with inspiring bundling systems at the end of line.

The latest ATS bundling system, in combination with the Powerpacker, were shown. Alois Tanner, President, explained the benefits of banding and was pleased about the support and feedback. New in the field is SMB – a German producer of bundling machines with its new SMBCOR, a successor of the well known Indupro. The solution has been well established and closes the gap between manual box collection process and the high-end Powerpacker. The SMBCOR is now installed at more than 45 companies.

Last, but not least, Bahmüller engineers made it possible to create and design another step towards zero defect delivery. A new level of folding supervision sensors with easy set-up and proper handling was introduced to the guests; Unique Eject and Boxflow®Control HMI.