According to the Falsified Medicines Directive (FMD) in Europe, every pharmaceutical manufacturer is required to adapt their packaging lines to guarantee that every box is safely closed until it reaches the consumer’s hands. Valco Melton, has developed a complete solution that guarantees that every medical box is perfectly sealed and protected against counterfeit until it reaches the patient.

Among all tamper evident alternatives, hot melt-based technology is the most reliable option since, once the package is sealed, flaps must be broken in order to open the carton. This system guarantees that its content has not been manipulated and the carton re-sealed. Apart from its effectiveness, this flexible technology can be easily integrated into any new or existing line and is capable of working at the highest speed lines without interfering with the workflow. Systems are available in different mounting configurations and are specifically engineered to minimise downtime and maintenance.

The complete solution consists in the Kube melt-on-demand demand unit, which promotes adhesive stability and reduces char by only melting adhesive as it is required and an EcoStitch™ all-electric hot melt applicator that produces accurate adhesive dot patterns and reduces adhesive usage by up to 75%. Combined with the VD2 controller, adhesive patterns can be easily customised and controlled. To ensure faultless delivery, the PackChek Vision Inspection System checks the correct placement and length of every glue bead and reports any error.

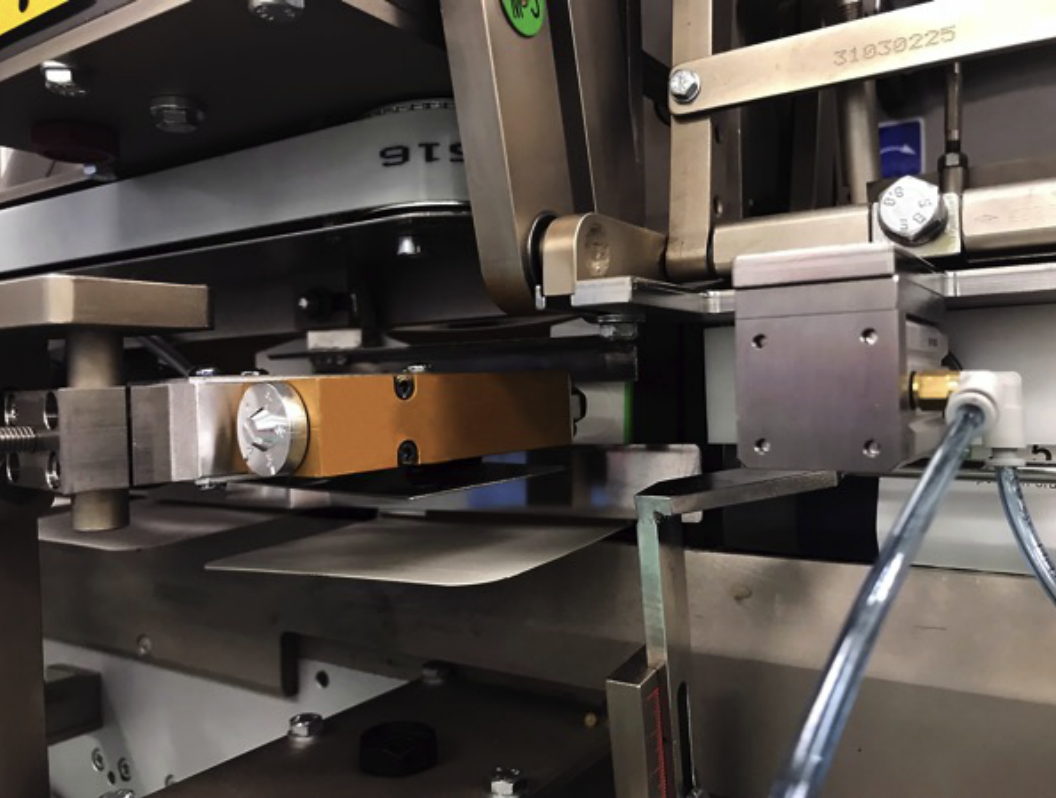

Hot melt applicator.