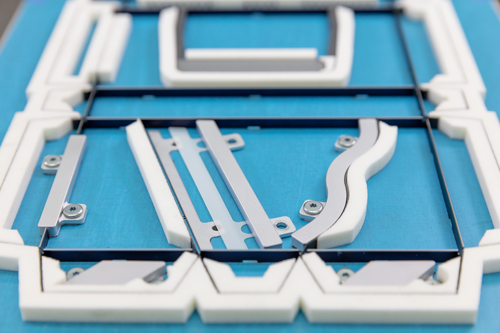

Marbach has recently introduced its new split height adjustable anvil, which helps in reducing make-ready times during reverse cutting. Customers using tools with a split height-adjustable anvil are impressed.

During reverse cutting, the board is not cut through, but the carton is scored from both sides in an offset position. This creates a special tearing mechanism that is popular for packaging. Reverse cutting requires a high degree of precision, because the board to be cut is thin and the tear mechanism only works well if the scoring is not too weak and not too strong.

Bernhard Reisser, Sales Manager at Marbach, explains, “For reverse cutting, success lies in adjusting the cutting-die and counter plate in such a way that the scoring of the carton works optimally. To ensure the make-ready process is as efficient as possible, we have developed the split height-adjustable anvil. It is height adjustable and thus provides an optimal, fast, and efficient way of setting up the reverse cutting from the front of the cutting-die. The height of the reverse cutting can be individually adjusted, quickly and easily and so can be set in the best possible way. Customers who use our new technology report significantly reduced make-ready times and perfectly working tearing mechanisms as well.”