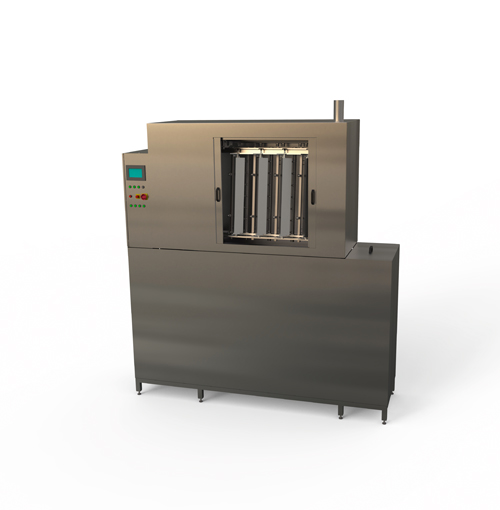

AkeBoose GmbH has recently installed the first of a new cleaning machine – Anicolor speedCLEANER 75 – at August Faller GmbH & Co KG in Waldkirch, Germany.

The Anicolor speedCLEANER 75 is specially designed to clean the ink chambers of the Heidelberg Speedmaster XL75 Anicolor printing press. The Anicolor press series is designed for cost-effective short print runs in offset quality. The ink transfer is done via open ink chambers and anilox rollers. To allow fast production and little waste, the Anicolor inks have a special formula. While this is advantageous for the printing process, it poses a challenge in terms of cleaning. Standard cleaning methods reach their limits given the adhesive and highly viscous ink properties.

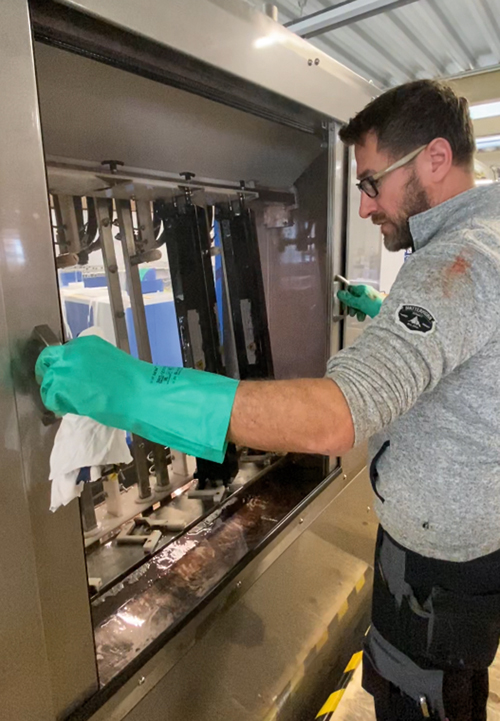

Fast and thorough cleaning of the ink chambers is crucial for the overall performance of the printing press. The Anicolor speedCLEANER 75 cleans up to four ink chambers per cleaning cycle in just 15 mins. The chambers are fixed vertically in the cleaning compartment, so that the cleaning detergent and ink residues can drain off quickly. The machine is equipped with both linear and rotating cleaning nozzles, which are placed strategically to cover all areas of the ink chamber.

For easy handling, the machine is operated via touchscreen and push buttons. General settings and cleaning parameters are set on the touchscreen, while the daily cleaning routine is simply done by activating pre-defined push buttons.

The cleaning detergent flows from the cleaning compartment through sedimentation trays, so that ink residues are separated and the cleaner gets purified before flowing back into the supply tank. This makes the process sustainable and the same cleaning detergent can be used for many cleaning cycles before it must be renewed.

The machine has been running at August Faller successfully and the feedback is positive.