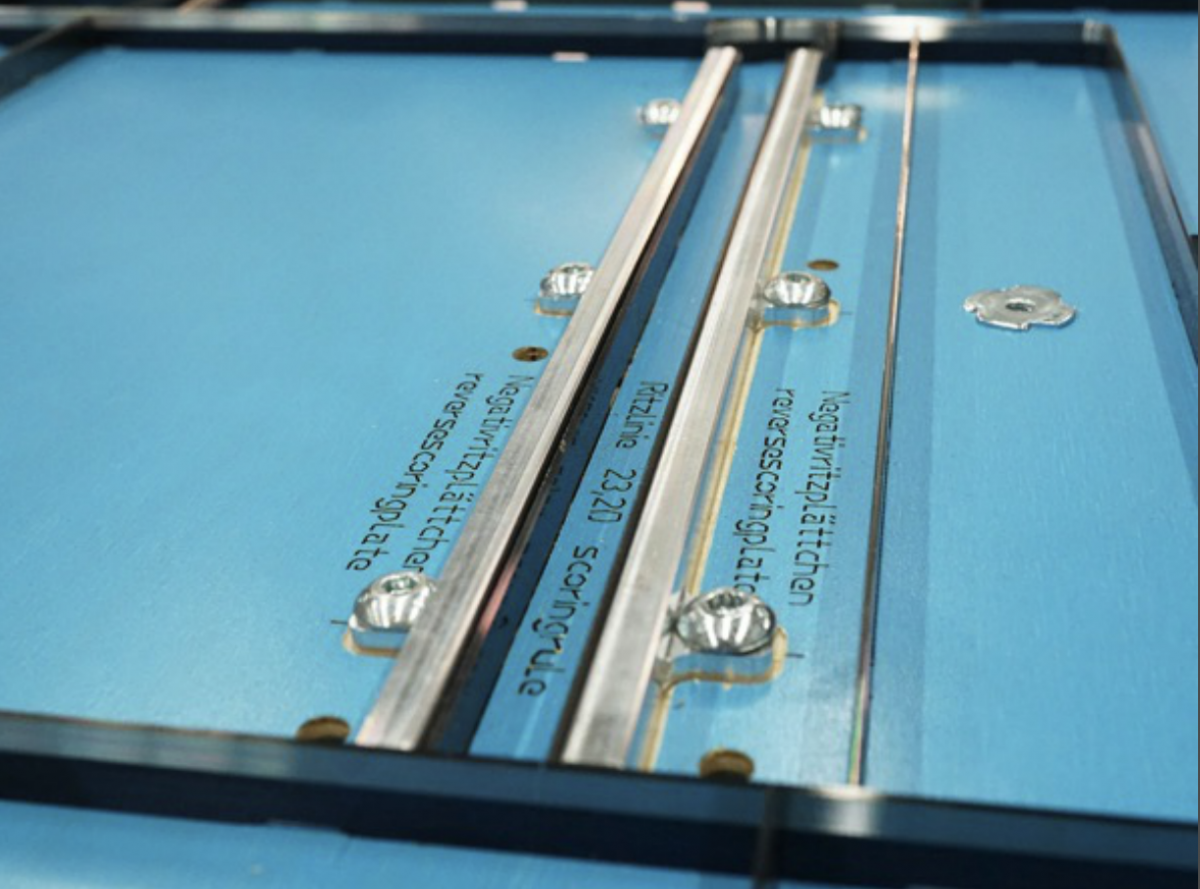

Germany based Marbach has recently presented its new technology designed to reduce the make-ready times for reverse cutting. The ‘height-adjustable anvil’ is becoming increasingly popular. Marketing Manager, Tina Dost explains, “By using the reverse-cutting technology, packaging can be equipped with a tear-open mechanism. Highest precision is essential for reverse cutting, as the cartonboard or corrugated board is not cut right through, but only scored from both sides. The reverse-cutting technology must work perfectly to ensure optimal functioning of the opening mechanism.”

With the height-adjustable anvil, Marbach customers can quickly and easily adjust the height of the anvils of their cutting-die by placing foil underneath. Each block can be individually set- up and thus optimally adjusted. This ensures flawlessly functioning opening mechanisms and sales-boosting packaging at the point of sale.