When you have enjoyed a reputation of innovation and quality for over 50 years, you do everything you possibly can to protect and even enhance it. That is certainly the case for Papercon Philippines, a packaging company that was established in 1963 and is widely known for its commitment to excellence and its clients, both nationally and internationally. Specialists in folding carton, food packaging and labels, Papercon boasts a wide range of printing capabilities, from basic one-colour applications to intricate, multi-colour designs, with or without metallic effects.

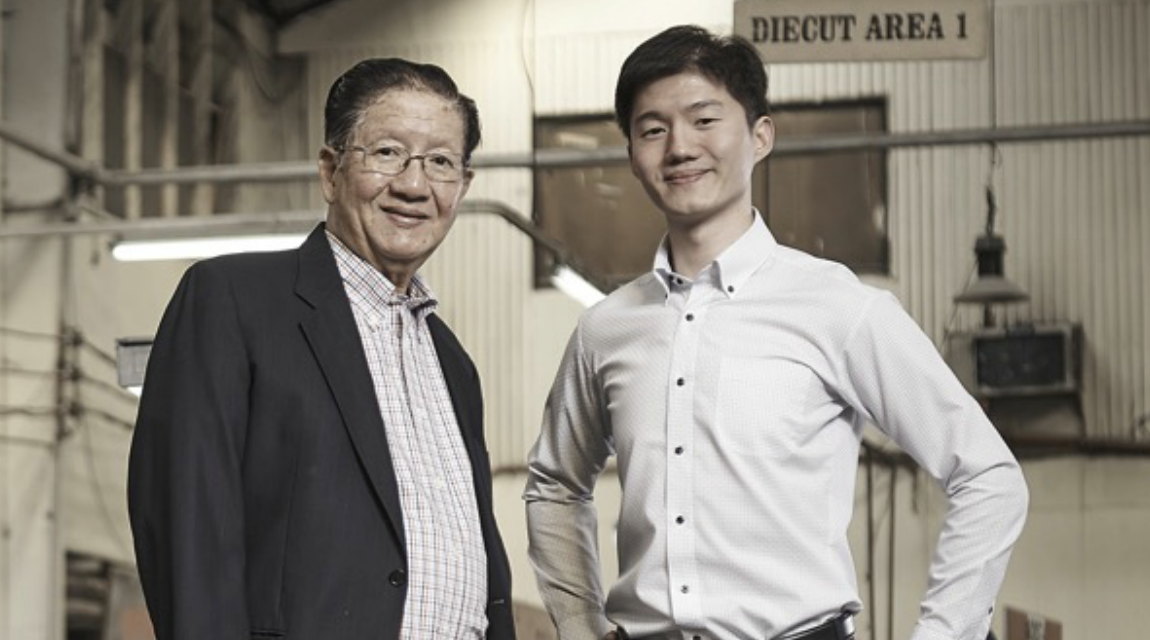

“Dependability and efficiency are possibly the two most important attributes in the world of packaging, and we pride ourselves in constantly delivering both,” said Kevin Pesengco, co-General Manager and third generation at Papercon. “In an era when we are seeing clients requiring shorter and shorter lead times with stricter quality controls and environmental sustainability, this can be challenging – but we have always managed to stay ahead of the curve.”

One of the main reasons for this is Papercon’s philosophy of cultivating and promoting creativity and innovation. The company invests with the very latest techniques, processes and methodologies to give its clients exceptional service experience. Its partnership with Bobst is the perfect example of its commitment to cutting-edge technology and service. The partnership stretches back to the 1990s, and Papercon still has a BOBST SP 102-SE Automatic Die Cutter that it purchased all the way back in 1995.

Being in action continuously for over 25 years is extremely impressive for a die-cutter, but that time will inevitably take its toll, even on Swiss engineering. This is where Bobst’s Re:generation programme comes in – Field Technicians come into the customer’s factory as expert troubleshooters, provide a thorough checkup of the machine and install a ‘Re:generation Pack’, which replaces any worn parts and enhances the machine to optimal modern standards.

When Papercon started noticing quality defects, such as misregistration and poor cuts due to general wear and tear sustained over so many years of use, it was time to implement the Re:generation Pack for the SP 102-SE die-cutter. Field Technicians spent several days at the Papercon site diagnosing any issues and installing the latest hardware to optimise performance. The outcome was instantaneous.

“Since the Re:generation Pack completion, we have seen an instant reduction in breakdowns and a significant increase in machine availability,” said Jason Pesengco, third generation owner and co-General Manager. “The press is essentially back to new peak condition and the overall quality of the finished materials reflects that. It is now running at optimal efficiency and we have complete confidence that it will produce dependable quality for many years to come. In a time when we are receiving more and more urgent orders from customers, this is a real benefit.”

Bobst conceived of the idea for the Re:generation Pack after hearing from so many customers who still relied on their innovative technology from two or even three decades ago. The idea is to bring these machines back to their original performance levels, enabling optimal efficiency and quality in an extremely cost-efficient way.

For Papercon, it is the latest example of Bobst being a genuine partner, not just a supplier. “We have always seen them as a provider of the best technology and a true partner,” said James Pek, Chairman of Papercon (Phils.) Inc. “We are very satisfied with their support ever since the beginning of our partnership.”

L-R: Jason Pesengco owner/co-General Manager and Kevin Pesengco co-General Manager.