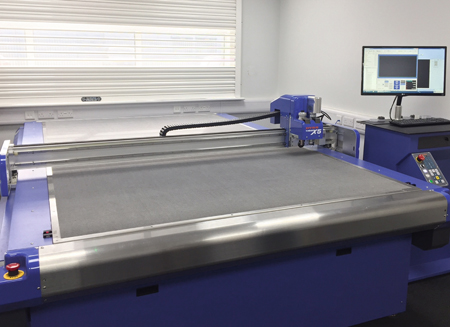

Trading out of Manchester since 1920, T.G. Nuttall Packaging Ltd has operated a CAD system and sample cutting machine for the last 20 years, allowing the company to offer bespoke design services and precision samples. While the original machine, which was supplied by AG/CAD Ltd, has provided excellent service over the years, the management team spent time considering the best options to update and upgrade their system. After looking at all the possibilities, they opted for a new DYSS X5-1625T to take the business forward for the next 20 years.

The large DYSS X5 cutter was selected based on its speed, robust build quality and flexibility – not to mention the longevity of the previous machine, combined with the service and backup AG/CAD delivered over the years. Initially the machine will be used to improve sample quality and turnaround, but the forward-thinking company also has its eye on the short-run market and the DYSS has the capability and 24/7 reliability to handle this work too. A sophisticated, intelligent camera system allows for print-face down cutting and creasing on corrugated, so low volume printed packaging and POS work is easily achieved.

With a wide selection of high quality carbide blades to handle even the most detailed work, the DYSS is capable of high speed cutting and creasing of all standard corrugated grades with excellent edge finish and accuracy. Depth controlled differential creasing means the machine can alternate pressure along the flute direction and cross flute giving the best creasing possible without splitting the liner. With the ability to add new tools to the machine in the future should they be needed, the X5 is also versatile enough to be able to handle plastics, honeycomb boards and even foam, so is more than capable of growing with the business.

Managing Director, Chris Bywater, comments, “We were amazed by how far the machines have come. Originally, we were just looking to replace our old sample table, but we see a raft of possibilities with the new DYSS. It’s an impressive bit of kit and the intelligence in the software control system has made it pretty much foolproof to produce high quality samples quickly and efficiently, as well as printed or plain short runs.”

He concludes, “We are always looking to innovate, often spending time at industry exhibitions checking what options are out there. It is clear that digital is becoming a growth area for packaging businesses. With the new DYSS, we are in a perfect position to exploit this sector and keep at the forefront of technology.”