Last year, the Hamburg printing company founded and run by the Siepmann family implemented a generation change in more than one sense. Firstly, Mark Siepmann took over responsibility for day-to-day management from his father Thomas. And at the same time, the company replaced a Rapida 106 dating from 2008 with a similarly configured press of the current series. Thanks to its higher automation, the new press promises even greater productivity and is contributing to an expansion of the company’s capacities.

Like its predecessor, the new Rapida 106 is a six-colour coater press with comprehensive automation features to enable fast job changeovers. After all, it is to be used primarily for the production of short and medium runs. Run lengths start at just 250 sheets and there are many jobs which require no more than 500 sheets. Frequent job changeovers are a routine element of daily production. “In this respect, the Rapida 106 is unbeatable,” says Mark Siepmann. Accordingly, it is hardly necessary to mention that DriveTronic SPC with Plate Ident headed the feature wish-list. The company is equally committed to sustainable resource use and environmental protection. VariDryBlue dryers, CleanTronic cloth-based washing systems and provisions for low-alcohol printing all contribute to this aim.

Siepmann considers itself to be a commercial printing company but has built up special capabilities to serve the pharmaceuticals industry. Specifically tailored press and workflow features, in combination with all the necessary certification, enables the company to produce several million patient information leaflets every year while further valuable business is derived from packaging production. Here, the typical numbers and volumes are just the opposite – short runs of fine packaging for premium consumer goods, pharmaceuticals and cosmetics have become their trademark.

The Rapida 106 must naturally offer the flexibility to match this broad product spectrum. The substrates handled by the press range from 40gsm paper for the information leaflets to solid bleached sulphate board and G-flute corrugated up to 1mm in thickness.

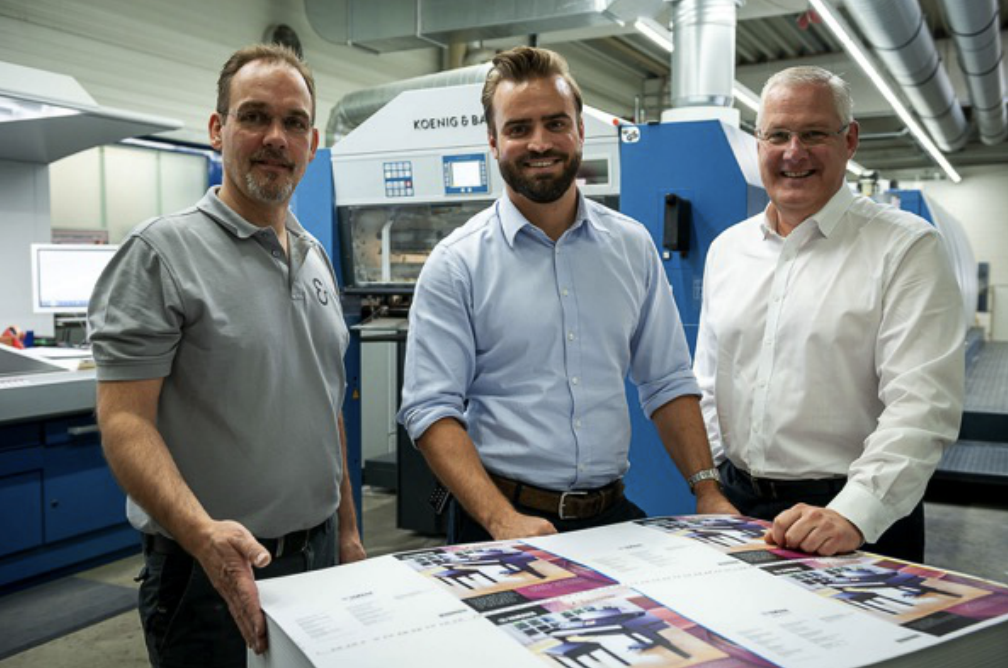

The new Rapida 106 is Siepmann’s dependable means of production for short and medium runs, much to the delight of printer Dirk Beckmann (left), managing director Mark Siepmann (centre) and Ralf Engelhardt from Koenig & Bauer (DE).