Valmet are launching a new-generation Valmet IQ Web Inspection System (IQ WIS) which enables board and paper producers to inspect and improve product quality in greater detail. IQ WIS works in real time, enabling immediate root-cause analysis and corrective action. IQ WIS is one of the integral elements of the Valmet IQ Process and Quality Vision system – another element is the Valmet IQ Web Monitoring System.

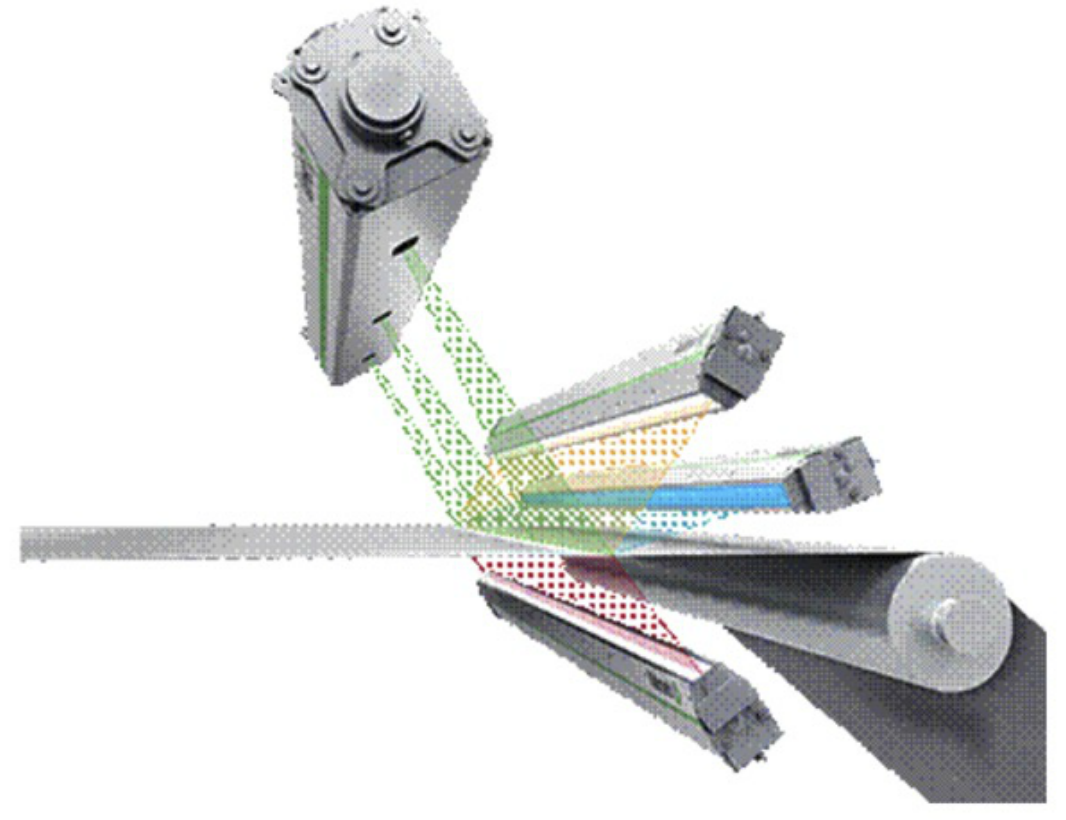

Valmet IQ Web Inspection System utilises intelligent 8K camera technology, which combines the best features of an area scan (matrix) camera and line scan camera technologies. It enables immediate identification of production that does not meet quality criteria through a wide range of technical features. High measurement precision can be reached even with higher maximum paper web speeds. More sensitive and reliable defect analysis can be achieved with multigeometry. It is also possible to replace several camera beams with one unit, resulting in cost-efficient, compact installation and lower service needs.

The latest IQ WIS technologies provide paper and board processors with the means to achieve profound quality monitoring and control. Unique lighting technology enables the detection of print-critical defects that have not been visible before. This illumination provides excellent opportunities for 3D defect contrasting. Particularly longitudinal structures and oil stains, for example, which are often hard to detect with standard lights, are also highlighted. Precise detailed defect classifications can be made by means of the MIDA (Multiple Image Defect Analysis) and the latest software algorithms based on artificial intelligence principles.

Valmet Industrial Internet solutions can utilise the data from the web inspection system to further benefit customers. A comprehensive process picture is created by combining the data from the quality control system and the machine vision system. By adding other key process data, it is possible to find optimal solutions to ensure desired process performance and end-product quality.

Multigeometry inspection gives more sensitive and reliable defect information. Unique lighting technology enables the detection of print-critical defects that have not been visible before.