ANC Machinery has released the new generation of the Kawahara Blanking machine for cartonboard and plastic cartons, labels and cards. The TXS-1100 is a joint Anglo-Japanese development and combines the robustness of the original design with the latest electronics, for increased reliability, safety and user experience.

With a colour touchscreen and servo motor functionality, the new machine can be operated completely intuitively from the first day and allows improved control over make-ready and blanking pressure. It is built with tri-rated components for compliance compatability throughout the world to genuine CE/UL/CSA standards.

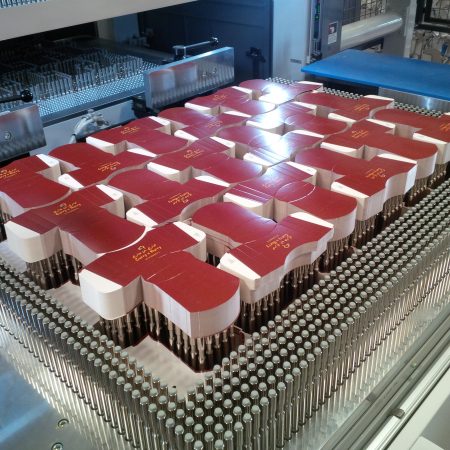

“Working closely with the safety compliance team at Omron Automation, our engineers have created what we believe is the best offline blanker available anywhere in the world today,” said Operations Manager Gary Compton. “The TXS-1100 continues the pioneering path of Kawahara in being the first such machine with pin-bed technology, and although often imitated, its inherent build quality has always placed it as the blanking solution of choice for small and multi-national packaging companies alike.”

The TXS-1100 fully blanks 80mm stacks of diecut sheets in under 30 seconds – equal to 200 sheets of 400µ board. Almost any die-line layout can be blanked. Make-ready is quick, using inexpensive templates which can be stored and re-used. When combined with the optional feeder and unloader, the TXS is even more productive.

New Omron HMI interface for the TXS-1100

Typical blanking example