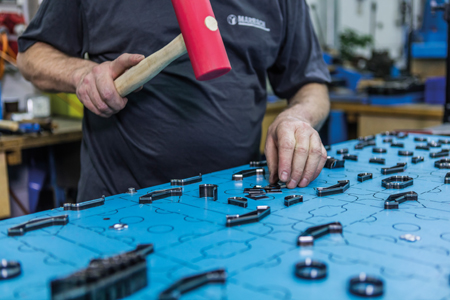

The Heilbronn, Germany-based cutting-die manufacturer, Marbach, has recently introduced its new modular system to its corrugated customers. With this new system, Marbach customers can be more flexible in ordering tool packages than had previously been the case. Because up to now, every job has been produced according to standardised customer specifications.

The tools could be adjusted individually to the intended purpose, but that meant a significant time requirement per order. Ingo Graham, developer at Marbach, explains, ‘‘This was often too time-consuming for our customers. That’s why they frequently waived any required individual adaptation needed for a single job. In order to provide more flexibility to our customers and to save their time, we implemented the modular system. With this, customers can quickly compile the appropriate tool package for every order.”

The Marbach modular system consists of three differently equipped versions: smart, performance and high-end. The smart option is cost optimised and is suitable for non-repeat orders. Performance is the output-optimised version, which is appropriate for jobs where production performance is the top priority. For long-term jobs involving very high quantities, Marbach customers can choose tooling packages from the high-end segment.