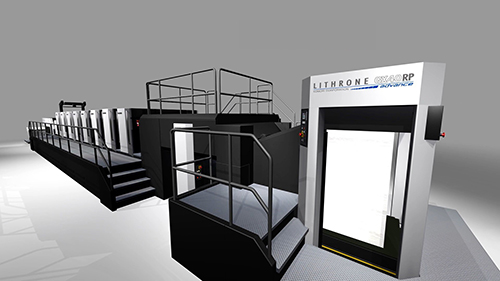

Komori America has confirmed that its Lithrone GX40RP and Lithrone GX44RP dedicated double-sided offset printing presses, are now available with the company’s advance technology.

The GX/G advance series of offset presses supports the thrust for both digital transformation and sustainability by offering full automation and a link to other production processes using centralized, digital technologies. The GLX40/44RP advance meets the demands of a new generation of printing by enabling dedicated two-sided printing without the use of a traditional, convertible perfecting unit. It reduces production time, increases the printable area of the sheet, improves the front-to-back register quality and substantially improves efficiency, making a focus on sustainability profitable for printers.

With the reverse printing technology inherent in the GLX40/44RP advance, there is no need to flip the sheet to print on both sides, resulting in design advantages, as the sheet does not need to have non-print gripper area for both the lead and the tail sides of the sheet. The 18,000 sph, multi-color presses require a gripper margin on only one side, saving about a half inch of paper per sheet or allowing more square inches to be available for image area, both of which generate less waste.

Beneficial to both commercial and packaging printers, the presses deliver high-speed, one-pass, two-sided printing with great stability, making it possible to print on commercial grade papers, board stock and synthetic substrates ranging from 40# to 20 pt. or 8 pt. to 32 pt., depending on configuration. Additionally, the GLX40/44RP advance are fully optioned presses that include Komori’s Full Asynchronous Automatic Plate Changing (A-APC), fully automatic color control, register control and defect detection (PQA-S) and Komori’s self-learning makeready interface (KHS-AI) that allows for short makeready times and reduced paper waste. Additional features of the GLX40/44RP advance include:

- Double-size impression and transfer cylinders with identical gripper systems;

- New Komori advance feeder and delivery technology;

- Improved front-to-back register accuracy;

- Computerized visibility of production results;

- Efficient use of consumables;

- Low cost of ownership and high ROI.

“The GLX40/44RP advance series adds a highly productive configuration that operates particularly well on heavy or light stocks, which could be challenging on a traditional perfector,” said Lance Martin, VP Marketing, Komori America. “The improvement in productivity is beyond expectations. Our customers who installed these presses have found them the perfect solution for delivering high production efficiency for both packaging and commercial applications while still meeting the environmental goals so important today.”