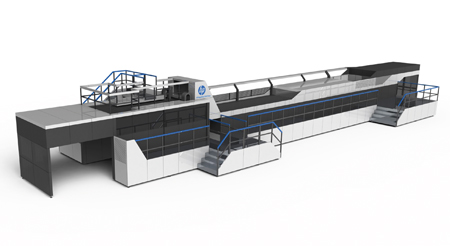

At interpack 2017, HP unveiled details on its HP PageWide C500 Press, confirming production capacity of up to 25 million sqm of production per year, powered by proven HP PageWide Thermal Inkjet Technology. A robust direct-to-board digital corrugated solution, the HP PageWide C500 prints on 1.3m wide corrugated sheets using an innovative media handling solution with a virtual belt. Announced at drupa 2016, customer beta testing is scheduled to begin at the end of this year, with commercial availability planned for 2018.

“This post-print corrugated solution from HP is yet another step toward digital conversion of traditional printing, offering savings in waste and setup time and improved supply chain efficiencies, in addition to high-quality graphics, easy customisation and versioning capabilities,” said Eric Wiesner, general manager, HP PageWide Industrial Division, HP Inc. “The HP PageWide C500 will help converters to differentiate with capabilities that only single-pass thermal inkjet and aqueous inks can deliver.”

The single-pass digital solution is designed for any type of corrugated facility for printing applications from shippers to high-quality graphics boxes, on coated and uncoated papers, without need for lamination, all in offset-replaceable quality. It will also offer a fully integrated stack-to-stack workflow, including an innovative in-line overprint varnish (OPV) solution. Converters will also benefit from a smooth integration to the HP PrintOS ecosystem and industry MIS, enabling an easy migration to digital with existing IT (MIS) infrastructure and prepress workflow.

“The C500 we saw in HP PageWide Labs looks promising. I’m excited about the print quality and colour gamut and what it will mean for our business. The C500 will be a game-changer. It will definitely help us grow new markets and expand within our high-colour graphics and display business,” said Richard Brown, President of The Boxmaker.

Louie DeJesus, CEO at Third Dimension Inc, added, “The C500 is undoubtedly a revolutionary machine. It’s going to change how we’re going to sell in the future. What impressed me most was the food safety part of the ink and the speed.”