At CITO-SYSTEM GmbH, progress continues. Cutting and creasing processes are optimised and tools and materials are developed further as needed. The company provides support with experience, know-how and training. The R & D department uses state-of-the-art high-speed video, simulators and measurement technology.

In the field of creasing technology, the company offers a large range of creasing systems. Its products stand for perfect creasing quality and optimum cost-benefit; a good example of this is ‘Ultimate’, the high-performance film-based creasing system. The flexible coating with a sturdy base ensures consistently high and constant creasing quality. Due to the back-springing shoulders, the same conditions are created for every crease. Both in laboratory tests and in practice, runs of over 500,000 sheets were produced with constant crease quality.

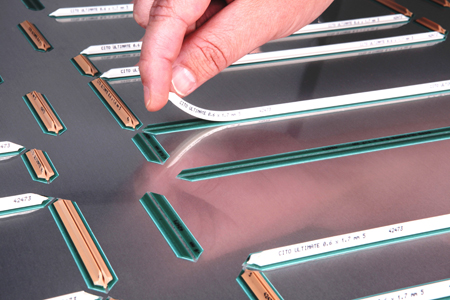

Cito’s ‘Ultimate’ is also ideally suited for repeat jobs and archiving in combination with 1mm cutting plates. The creasing matrix sets itself apart due to perfect handling with fingerlift and can be easily trimmed with the knife. Excellent adhesion on the cutting plate and residue-free removal thanks to EasyFix technology ensure user-friendly application.

The success of ‘Ultimate’ in the processing of solid and carton board as well as the demand of corrugated converters prompted Cito to expand its product range to include microflute and standard corrugated board. Especially with these materials, both high runs and absolutely constant crease quality are decisive factors. The company says ‘Ultimate’ reduces breaking of the crease in corrugated board. The chamfered outer edges prevent visual damage of the surface. The flexible coating compensates for fluctuations in the corrugated and allows constant creasing quality with the highest quality standards. The patented creasing system is available in about 600 different sizes.

Further information can be found at the company’s website.