Green Bay Packaging, Inc., a leading producer of folding cartons, corrugated packaging and point-of-purchase displays, has installed the 1000th Very Large Format (VLF) printing unit from Heidelberg. The new Speedmaster XL 145-7+L with UV is set to be installed early this year and is the latest addition to the Wisconsin-based company.

The VLF press, equipped with Prinect Inpress Control and Prinect Inspection Control, will run alongside a Speedmaster CD 102-7+L and an existing Speedmaster XL 145 with UV. According to President and CEO Will Kress, its first XL 145 provided increased capacity and faster set-up times. The new 57” press is expected to further improve productivity throughout the plant.

The new Speedmaster XL 145 features 7 printing units plus a coating tower and can handle both conventional and UV inks and coatings; it comes equipped with a 37 ft. extended delivery for maximum curing at full speeds across a wide range of substrates. Prinect Inspection Control examines each printed sheet for errors and material defects to ensure a reliable and flawless finished product.

The high level of automation and intelligent press control simplify all work steps and minimize makeready times, energy consumption, and paper waste. With speeds of up to 18,000 sheets per hour, Heidelberg’s VLF platform is fit to serve both the short-run display market as well as high-volume leaders in the packaging industry.

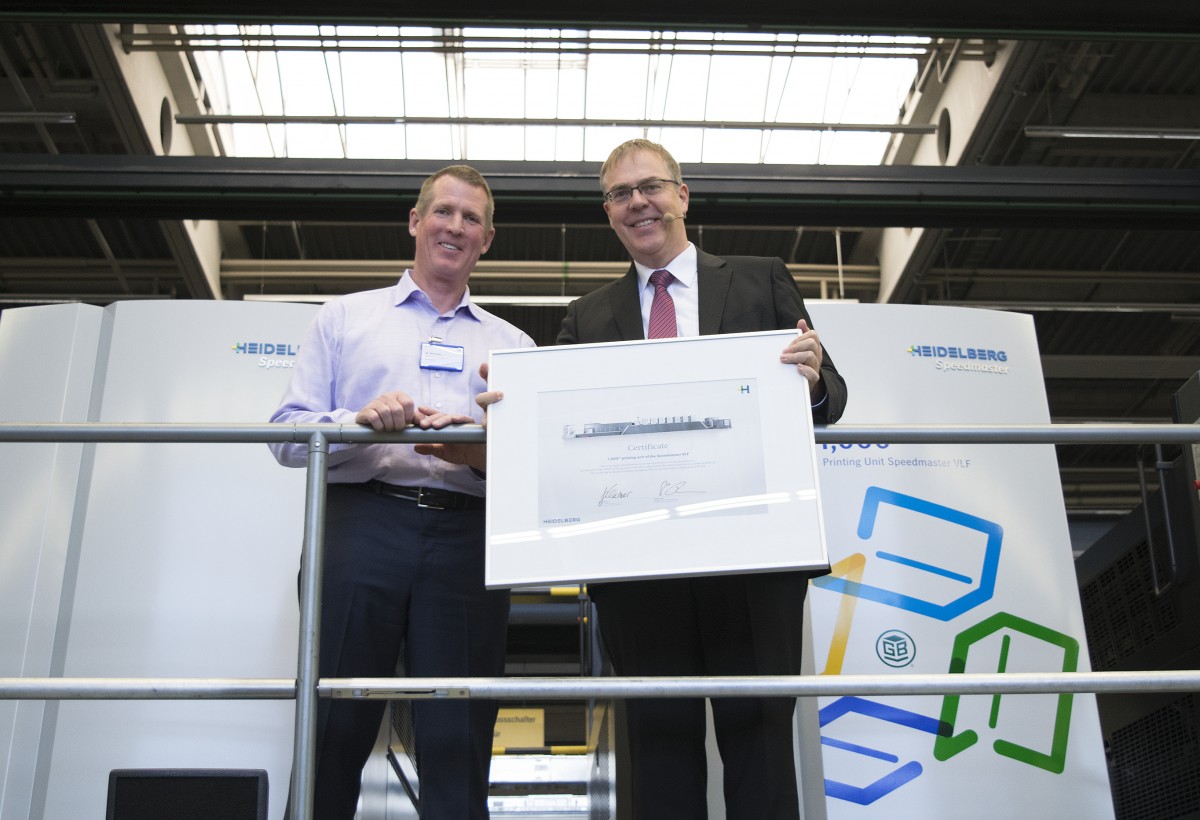

Green Bay President and CEO Will Kress (left) and Harald Weimer, former member of Heidelberg Management Board