Preston, UK-based Diecut UK Ltd, confirms it has installed a Goldline 2500 die-cutter at Ridge & Tyler (Print & Packaging) Services Ltd. Health and safety was the top priority for Ridge & Tyler when they looked into replacing an aging VK2500 clamshell platen. “The Goldline 2500 ticked all the HSE boxes and was modified to suit their method of set up, meaning all cutting tools could also be run on their semi-automatic machines,” explains Steve Waterhouse, Managing Director of Diecut UK. “The installation ran smoothly and the Goldline was running jobs the next day. It is still early days, but the operators at Ridge & Tyler are delighted with the Goldline and have found it very user friendly. They are already noticing set up times to be much quicker than the previous clamshell platen, resulting in an increase in productivity.”

The Goldline is available in 10 different sizes with a die-cutting capability varying from 890 up to 3200mm, with options for scissor lift tables, heated bed and wide opening for honeycomb board or foam.

Pete Ridge of Ridge & Tyler says, “We chose Diecut UK as they offer the best alternative to the dated clamshell platens and we will now be looking to replace our other three platens with Goldlines in due course.”

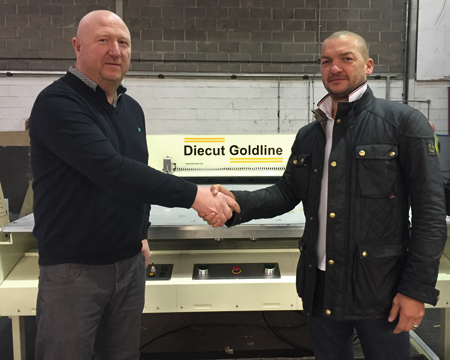

Left to right: Mark Tyler, co-owner of Ridge & Tyler (Print & Packaging) Services Ltd, with Steve Waterhouse of Diecut UK.