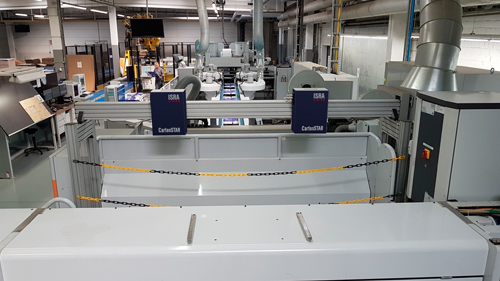

At its facility in Mannheim, Germany, DS Smith assures print quality with the CartonSTAR 100% inline inspection system from ISRA VISION, a leading provider of surface inspection systems. The system distinguishes between quality-relevant print errors and non-homogeneous textures on the corrugated board surface. Continuous quality and process control of the printed image also permanently reduces product costs and ensures that resources are used sustainably.

On the recently installed Mitsubishi EVOL 100 flexo folder gluer (pictured below), DS Smith Mannheim produces various types of boxes and trays for food, technical products and hygiene items. In order to remain in line with the company’s own standards, printed image monitoring was needed. The installation of an inspection system is practically standard in the sector, making it an absolute necessity. Positive experiences from colleagues at the sister plant in Arnstadt drew the attention of DS Smith’s Packaging Division to ISRA.

The CartonSTAR inspection system enjoys a high level of acceptance among the machine operators in Mannheim, who say they appreciate the two-camera solution with high-performance backline LED lighting. The system particularly benefits users directly on the machine, as the complete inspection of the printed images significantly minimises the risk of defective printing.

The 100 % monitoring of the printed image reduces the number of complaints significantly – despite the constantly increasing demands of customers. Even single defective sheets with errors in the printed image are reliably detected and removed before further converting. The system is capable of ‘ignoring’ the inhomogeneous surface structure of the corrugated board, while still reliably identifying all quality-related defects – even at maximum speeds of 18,000 sheets per hour. All defects are accurately classified.

Daniel Malolepszy, Head of Production at DS Smith Mannheim says, “This feature allows relevant and non-relevant defects to be detected, thereby making a crucial contribution to the commercial success of the CartonSTAR system. The fact that the classification can be conducted quickly and easily in line with the customer’s needs increases the productivity of the printing process significantly. The advantages of using the inspection system can be clearly measured in improved productivity and the falling cost of complaints.”

By documenting all incidents, the inspection system also enables verifiable quality management. With inspection during the printing process, DS Smith can guarantee continuous feedback on the printed image and material quality.

“For us, CartonSTAR is a well-conceived system,” adds Malolepszy. “A further benefit is the excellent experience with ISRA’s service staff. With the ISRA inspection solution, we have increased the quality of the products, permanently reduced product costs and ensured that resources are used sustainably. Also ensuring complete process control, the system strengthens our market position and secures a crucial competitive advantage.”

ISRA Vision says that return-on-investment is generally achieved within 12 months.