KBA has been supplying sheetfed offset technology to the Hanau Germany, facility of DS Smith for several decades. Other DS Smith locations also work with Rapida sheetfed offset presses, predominantly in large format. So it was no great surprise that the new production centre for display and consumer packaging in nearby Erlensee will again be relying on highly automated large-format Rapidas from KBA-Sheetfed.

A new KBA Rapida 145 has already been taken into service and further large-format Rapidas were relocated to Erlensee from the old print centre in Hanau. Before reinstallation, however, they were treated to a thorough overhaul and a number of state-of-the-art retrofits. All three presses are integrated into automatic logistics systems, which handle substrate transport along the whole chain from initial delivery through to post-press finishing and conversion.

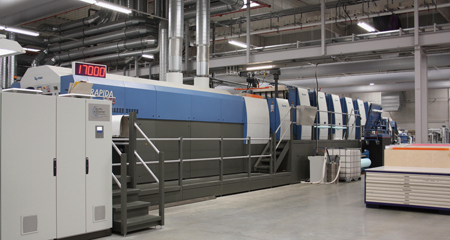

The new six-colour Rapida 145 with inline coating unit is a high-speed model engineered for production speeds up to 17,000 sheets per hour. Comprehensive automation lays the foundation for efficient packaging production. Inline quality management is another extremely important aspect. With QualiTronic ColorControl, ink densities are measured and controlled sheet after sheet over the whole length of a run.

The first of the relocated Rapidas came back on stream at the new facility last autumn. With its new grippers and retrofitted logistics components, it is set for many more years of reliable service. After recommissioning, work began on the overhaul of the second large-format Rapida. The whole relocation project was then completed at the beginning of 2017.

A new six-colour Rapida 145 coater press is the latest eye-catcher in the print centre