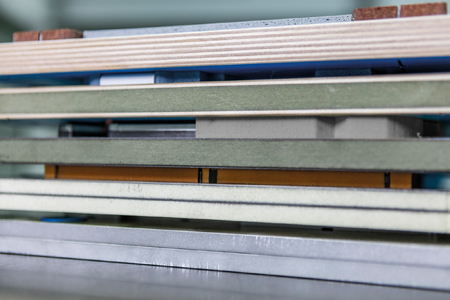

Marbach offers an extensive portfolio of dieboards. The suitable dieboard can be selected according to the requirements of the customer or the particular order.

The dieboard forms the basis of a cutting-die. The contours of the packaging are first inserted into the dieboard, then the cutting and creasing rules are positioned and finally the appropriate rubber coating is applied.

For standard requirements Marbach offers multiplex dieboards made of high-quality birch wood. Due to its slow growth, birch wood is very firm and even. This makes it laser capable and suitable as the basic material for a cutting-die. The crosswise gluing gives the multiplex dieboard the stability it needs and ensures a long service life.

Those who also want to do something for the environment could decide on the Marbach greenplate, as it consists of 30% birch and 70% secondary material. This environmentally friendly secondary material comes from sustainable forestry. Due to its design, the greenplate is subject to only minimal height tolerances. This makes it ideal for use with embossing and braille. Its flatness and good technical properties ensure optimum pressure conditions during the die-cutting process.

Dimensionally stable dieboards are used when demands on durability and precision are higher during die-cutting. Due to material choice and construction, they are designed to remain dimensionally stable even under hygroscopic influences and strong climatic changes.

The Marbach solidplate is the entry-level model in the class of dimensionally stable dieboards. The solidplate is based on two steel plates applied to the proven Marbach greenplate core. Due to the steel surface, this construction enables a quick and easy rubber change. Multiple reknifing is possible for long runs.

The dieboard made of duramar is the flagship in the class of dimensionally stable dieboards. Glass-fibre-reinforced plastic is combined with steel plates. Depending on how these elements are combined, different versions of the duramar dieboard are available: eco, plus or performance. These dieboards are also non-hygroscopic. They are distinguished by their high dimensional stability and extremely long service life. They can be reknifed often and have an outstanding accuracy of fit, even with large machine formats.

The aluminium dieboard stands for very special requirements. It is not only stable, but also has a high thermal conductivity. This makes it ideally suited as a heatable dieboard. For diecutting and creasing of plastics. But also for the highest hygienic requirements.

Head of Business Development, Jan Brunner: “Our dieboards are as individual as the needs of our customers. Depending on the order, layout, quantity and requirements, we work with our customers to select the right dieboard for optimum die-cutting results and maximum performance in the production of packaging. This gives our customers the assurance that they are using the perfect tool for their requirements. Leading to the best possible results.”