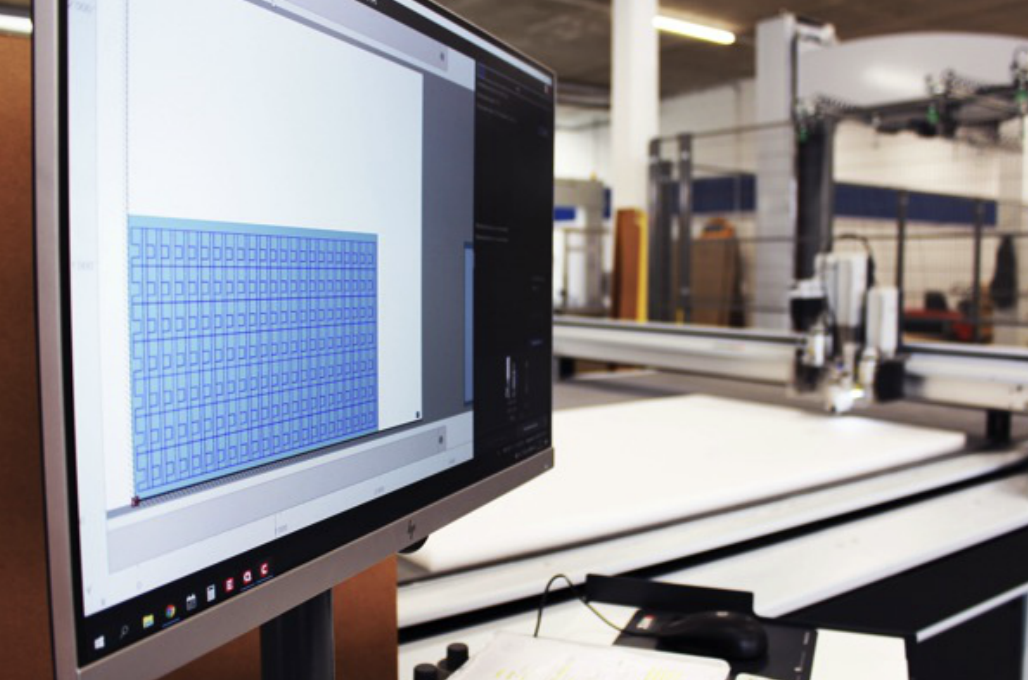

Wellpack AG in Einsiedeln, Switzerland has recently invested in automated Zünd cutting technology. At the heart of the system is a Zünd G3 cutter with extended beam clearance for processing packaging foam. Also included for completely automated material handling is the BHS150 Board Handling System.

The fully automated board loading/unloading system, combined with a high-performance G3 cutter with expanded clearance, provides uninterrupted, high-throughput capacity for foams, cartons and corrugated. The 1.5 m stacking capacity and high level of automation make the BHS Board-Handling System efficient. Pallets of raw material can now be moved into the loading unit and then fed onto the cutting system without further manual intervention. This translates into a significant reduction in material handling.

It’s an innovative system that makes use of a conveyor belt for unloading the material which eliminates the need for bridges to keep cut pieces in place, which reduces the time and effort involved in separating cut parts from waste and further enhances the efficiency of the system.

A G3 cutter with automatic Board Handling System BHS150 helps Wellpack meet the challenge of ever shorter delivery times