C&T Channel Matrix (C&T), continues to support die-makers globally through their distributor network to understand how Speedpins can maximise stripping performance.

Since its launch in 2018, the revolutionary pin is aimed at the die-cutting industry and has already become a favourite with many folding carton and die maker companies. C&T has sold in excess of two million pieces since its launch.

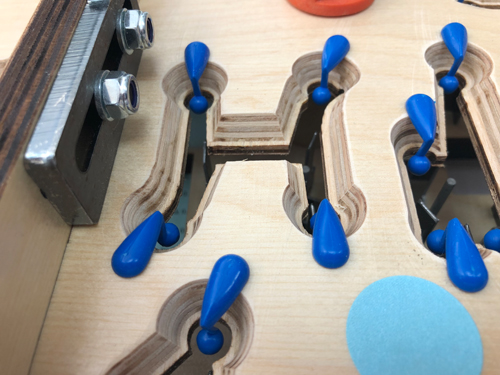

C&T says that Speedpin offers a reduction in pre make-ready time and improves conversion efficiencies. It is fitted in the female stripping board by the die maker and eliminates the need for stripping frames and bottom pins, thereby saving time, reducing consumable costs and increasing machine efficiency. It also means no waste is left hanging on the bottom pins, reducing the likelihood of stoppages.

To assist distributors with the implementation of Speedpin, C&T can support customers with BCSI PackDesign CAD software. The software enables C&T to take the customer’s layout in various formats such as CF2. DXF. The layout is programmed so the customer can produce a full set of tooling, incorporating the Speedpin. This includes male and female stripping boards and nicking positions for the cutting die within the design. This completed layout is sent back to the customer so they can manufacture and cost the tooling correctly. The main benefit for this service is the set of tooling runs first time.