Allard Emballages Brive, part of Hinojosa Group, have signed an agreement for a Koenig & Bauer Celmacch five colour ChromaCUT High Tech 2800.

This is not the first cooperation between Koenig & Bauer Celmacch and Hinojosa Group. Three Celmacch flexographic printers Chroma High Tech are already present at the Hinojosa factories: the first one was installed in 2014 in Cipasi, the second one in 2017 in Envases Rambleños close to Córdoba, and the third one at the Xàtiva’s headquarters between the end of 2017 and January 2018.

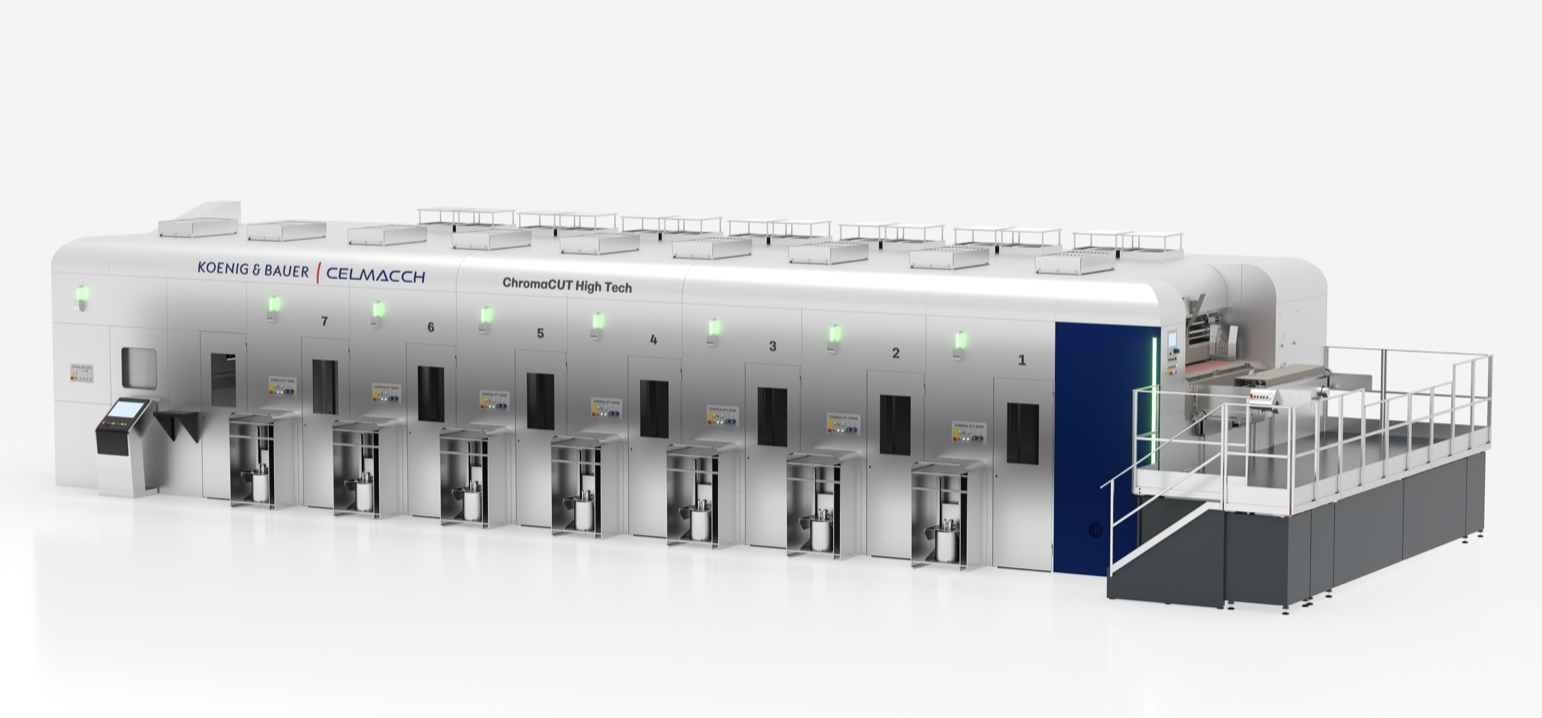

Allard Emballages placed the order in January for the latest-generation ChromaCUT High Tech, fully driven by direct motors. With a high degree of automation and considerably shorter makeready times, the new machine will have a working width of 2,800 mm, and a production speed up to 10,000 sheets per hour.

The ChromaCUT 2800 will be equipped with one feeding unit, five print stations with vacuum transport sections, a rotary die-cutter, vacuum bundle stripping stacker and motorised modular belt conveyor to be placed after the stacker and before the breaker. The new line will be delivered at the end of Summer 2024 and installed at the Brive-la-Gaillarde plant, in France.

Luca Celotti, CEO, Koenig & Bauer Celmacch, explains, “Chroma CUT is a combination of high print quality and a perfect rotary die-cutter. It is not only a high-productivity machine, but it also provides high-definition printing for highest quality results. Innovation, continuous investment in the latest technological solutions, exclusive use of finest-quality components, durability, strength, reliability, and maximum performance in the long term, are the key success factors of our ChromaCUT rotary die-cutter.”