Back in February, Bohui Paper Group contracted Voith to supply a new board machine. BM 4 will be built at Dafeng in the Chinese province of Jiangsu and following completion will be one of the largest board machines in the world. Voith will supply the complete XcelLine process line from wet end process to winder.

By December 2018 the new BM 4 will operate at a speed of 1,200 m/min producing folding box board with a basis weight of 250 gsm. The production line offers a range of special technical features that both improve the quality of the finished board and reduce energy consumption. The wet end section of the BM 4 impresses with a new Clean Design concept that achieves particularly high runnability. The use of a Triple NipcoFlex press not only ensures tremendous dewatering efficiency while preserving volume, but also achieves a smooth board surface. The scope of supply also includes three MasterJet Pro headboxes, a DuoFormer DII, four TurboDryers and the energy-efficient qDry Pro non-contact drying system. Moreover the BM 4 is equipped with EcoCal Hard and EcoCal Soft calenders, a Sirius winding system as well as two VariFlex winders.

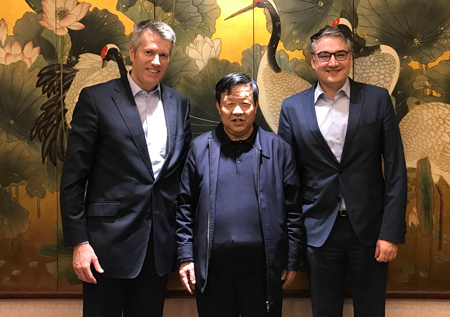

L to R: Andreas Endters, President Business Line Projects Voith Paper, Yang Yanliang, Chairman Bohui Paper Group and Thomas Holzer President Voith Paper Asia