Smart Factories, Technology Lounges and Customer Reference Sites have been now set as the preferred engagement model with converters, as BOBST launches a new strategy to support its vision that will help to shape the future of the packaging world, reflecting corporate values and responsibilities.

The number of industry events and tradeshows has increased significantly over the last decade and at the same time, the communication technologies offer new ways to share content. To engage with its customers more effectively, BOBST is set to evolve its current Competence Centers to the next level, providing all customers and prospects with new ways to access product and solution demonstrations. Over the last few years, the Competence Centers have been growing and the investments made are significant. They have become the preferred place to showcase live customer experiences and to validate investments.

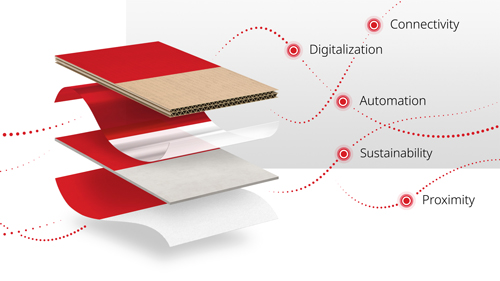

This transformation will lead into new Smart Factories, which will encompass Technology Lounges, Partnerships and Application Experts to demonstrate complete end-to-end solutions where customers will be able to touch and see everything required to produce a label, pouch or box. From substrates processing, to job preparation, colour management, printing, tool preparation and converting, all with the option to test specific jobs from converters.

“We have started to virtualise the customer experience with live streaming demonstrations – across all equipment in our existing Competence Centers, providing an engaging customer experience with less traveling constraints. There will be further information on these new ways of engagement soon,” says Jean-Pascal Bobst, CEO. “BOBST is reducing its presence at industry tradeshows and thereby dramatically reducing the environmental impact. As a result, we have decided not to attend drupa and other industry trade shows in 2021, while maintaining a limited participation in Asia.”

He concludes, “BOBST is at the start of a new journey, which will enable us to engage with our customers in a quicker, more effective and more personalised manner, reducing the environmental burden and shaping the future of the packaging world.”