ERO Gluing Systems is at the forefront of integrating the benefits of Artificial Intelligence into the gluing sector with ERO-DL, the cold glue inspection technology.

After over a year of research, ERO’s Engineering Department has perfected the ERO-DL cold glue control technology, whose advantages surpass those of a traditional inspection system. The ERO-DL adhesive inspection system incorporates cutting-edge deep learning technology, enabling automatic parameter setup for every processed carton. Trained with an extensive database of glue pattern images, the AI eliminates the need for manual presetting or adjustment by operators, thereby streamlining the production process, even for new orders.

“We are excited about the launch of the ERO-DL system. We are confident that it will greatly assist our customers by shortening pattern setup times and offering the smartest way to apply glue patterns,” says Francesca Notari, General Manager, ERO. “All of this results in reduced machine downtime for batch changes.”

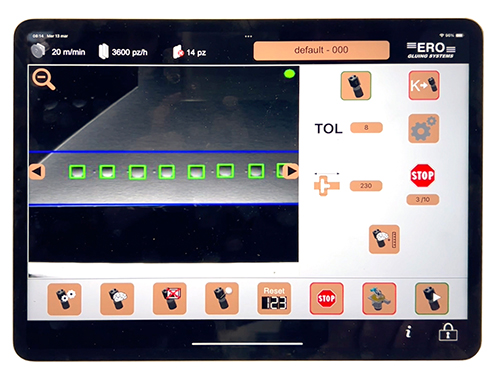

Control of the ERO-DL technology is done through an iPad that seamlessly integrates the control of cold glue applicators and pattern inspection into a single device. This innovative system not only enables remote connectivity for controlling and checking parameters from any location but also enhances performance through customised remote training on special formats.

The ERO-DL technology is controlled through an iPad that seamlessly integrates the control of cold glue applicators and pattern inspection into a single interface.

The ERO-DL camera operates with the precision of a human eye: it can detect adhesive points and beads on any surface. This includes delicate substrates such as aluminium or other reflective surfaces, which have posed a real challenge until now. The use of adhesives with UV additives is also no longer necessary, making it the ideal system for the food industry.

The system comes standard with the ERO-GTE 13 applicator that can apply glue dots to get important glue savings , although it is compatible with any system on the market.