The Agergaard Group will shows its range of printing equipment and printing consumables to promote a cost-efficient and trouble-free printing process at drupa, Hall 15/A31.

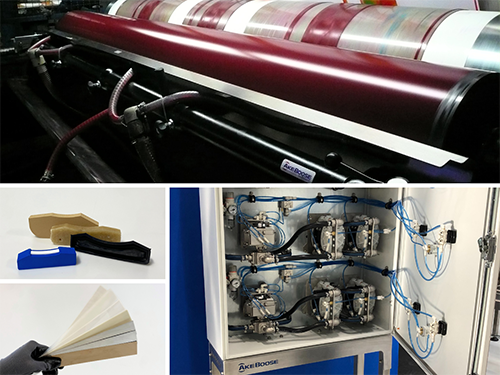

It will promote its AGSflexo end seals and doctor blades for enhanced press uptime. Matched to the respective printing application, these printing consumables ensure optimum sealing and ink metering performance in printing and coating units.

AkeBoose chamber doctor blade systems, ink handling systems as well as inline printing and marking units for repeatable high-quality printing results, ease of use and low operating costs will also be shown.

Visitors from the offset industry can discover plug and play chamber doctor blade technology for inline coating towers paired with the LQl coating supply unit, which makes it possible to efficiently process special coatings with low volume in the loop and thus very little residual varnish in the system after application. For the corrugated industry, it’s all about durable and robust ink handling and ink application systems for printing widths of up to 6 m. The 100% stainless steel NOVA XLS chamber system version is forever-corrosion free and made to withstand bouncing.