C&T Channel Matrix has confirmed the launch of its new matrix, 8 PRINT. This innovative fibre-based matrix is designed specifically for corrugated board and offers a range of benefits for die cutting applications.

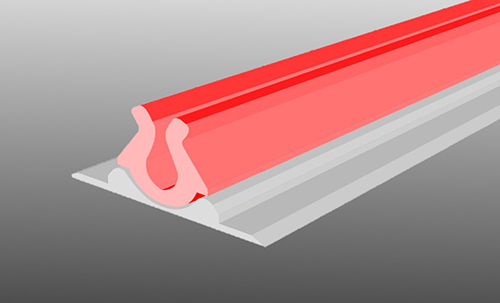

The key feature of 8 PRINT is its rounded channel design. This channel allows for the efficient and precise die-cutting of corrugated board, from microflute to triplewall, without creating breaks or cracking. This ensures that the finished product looks neat and professional while minimising production waste.

In addition to its excellent die-cutting capabilities, 8 PRINT is highly resistant, making it suitable for high volume production runs. Its durability ensures maximum punching precision and reliability for consistent results.

Made from a single milled piece, 8 PRINT offers exceptional quality and longevity. Its design is specifically optimised for corrugate cardboard, delivering excellent performance even in the flute direction. When selecting the appropriate 8 PRINT matrix, users should consider the width and thickness in relation to the flute direction and the grammage of the paper. This will ensure the best performance and results.

“We are excited to introduce our new matrix, 8 PRINT, to the market,” said Simon Shenton, Managing Director, C&T. “This special fibre-based matrix is designed to meet the needs of corrugated board conversion. We already have many types of specialist Matrix for the corrugated sector including Corrugate, Hinge and Reverse Bend. The introduction of 8 PRINT further strengthens our portfolio and showcases our dedication to meeting the evolving needs of customers”.