Edinburgh-based Thomson Print & Packaging Ltd was founded in 1998 by Jim and Veronica Thomson, when the company was purchased from Dennis Virtue, trading under the name Dennis Virtue Printers Ltd. At that time the company was running a pair of Heidelberg GTO two-colour presses, and a cylinder foil blocker out of a 1,500 sq ft factory based in Leith.

In 2000, the company moved to a 5,000 sq ft factory near Portobello. Here, print capacity was expanded, with the addition of two new B3 format Heidelberg presses — a four-colour and a five-colour — and a second cylinder foil blocker. The company then moved again in 2014 to larger premises and added a Gietz FSA 870 foil blcoker, followed by a Heidelberg XL75 five colour press in 2016 – this was the turning point when the company started to focus on the growth area of folding carton. A second Gietz FSA 870 followed and presented the family owned company the opportunity to really grow its customer base.

Moving again

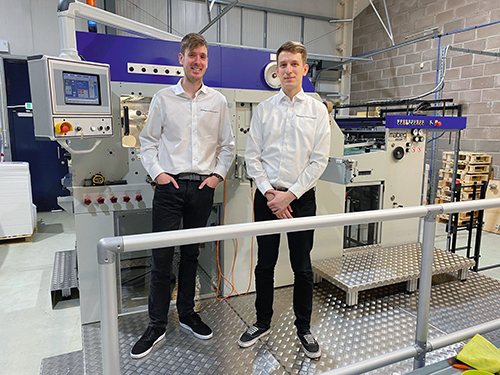

“The facility in Loanhead started to get a little small for us, so I sat down with my two sons – both of whom have worked in the company for over a decade – and we had to make a serious choice as to whether we aim future growth at labels or folding cartons,” explains Jim Thomson, Managing Director. “Without hesitation, they both said cartons was where they wanted to be, so we looked at how to grow the business accordingly.”

The simple answer was they needed more equipment and more space. So the hunt began in early 2023 for a suitable premises and within a matter of months, they had found a site they felt would be right for them.

“We had seen a site in Edinburgh a year or so earlier, but it was not available,” explains Jim Thomson. “However, the 12,000 sq ft site came to market in 2023 and we were quick to jump in.”

The company then set about enhancing the factory, with a view to installing not only the existing range of print and embellishment equipment, but also two new lines. “This new site allows us to install large format cutting and creasing equipment from Heidelberg so we can develop our carton business and a new gluer from BOBST,” continues Jim Thomson.

“We visited a couple of suppliers, but the Heidelberg Easymatrix provides us with the best solution for our requirements,” says Michael Thomson, Production Director. “The machine is being installed in March and prior to this, I am spending a few days in Germany getting intensive training so I fully understand its capabilities.”

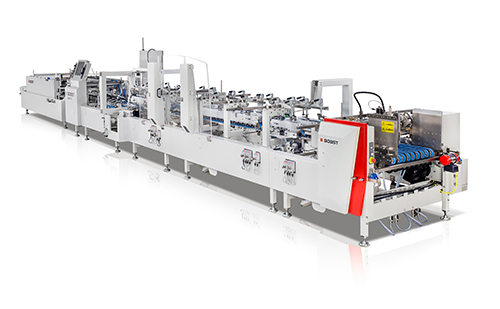

“Having previously outsourced this type of finishing work previously, our control over quality by doing these operations in house will be substantial,” adds Barry Thomson, Sales Director. “With the new 12,000 sq ft site and our growth ambition in developing our carton business, we also decided to choose a NOVAFOLD folder gluer, capable of finishing difficult carton styles in one pass.” The new folder gluer arrives in May this year.

Big plans

“We supply a wide range of print and packaging products to mainly the drinks Industry both in the UK and Ireland,” concludes Jim Thomson. “The reaction from our team to this £1.5m investment has been very good and they were all really helpful during the month or so it took us to move into the new facility. We are in the process of employing a further four people as we continue to invest in the future of the company and our aim is to take the business from the current £2m per year turnover to £3.5m within the next 18 months. With this latest move, we are closer to our main customers, enabling us to reduce our carbon footprint as well.”