Together with politicians, media representatives, employees and numerous customers, Germany-based Thimm celebrated the inauguration of its new digital printing press at the Alzey site in June. With its investment in the new machine, the company is strengthening its printing expertise in digital web press printing, not only offering its customers high-quality packaging printing, but also the digitalisation of their supply chains.

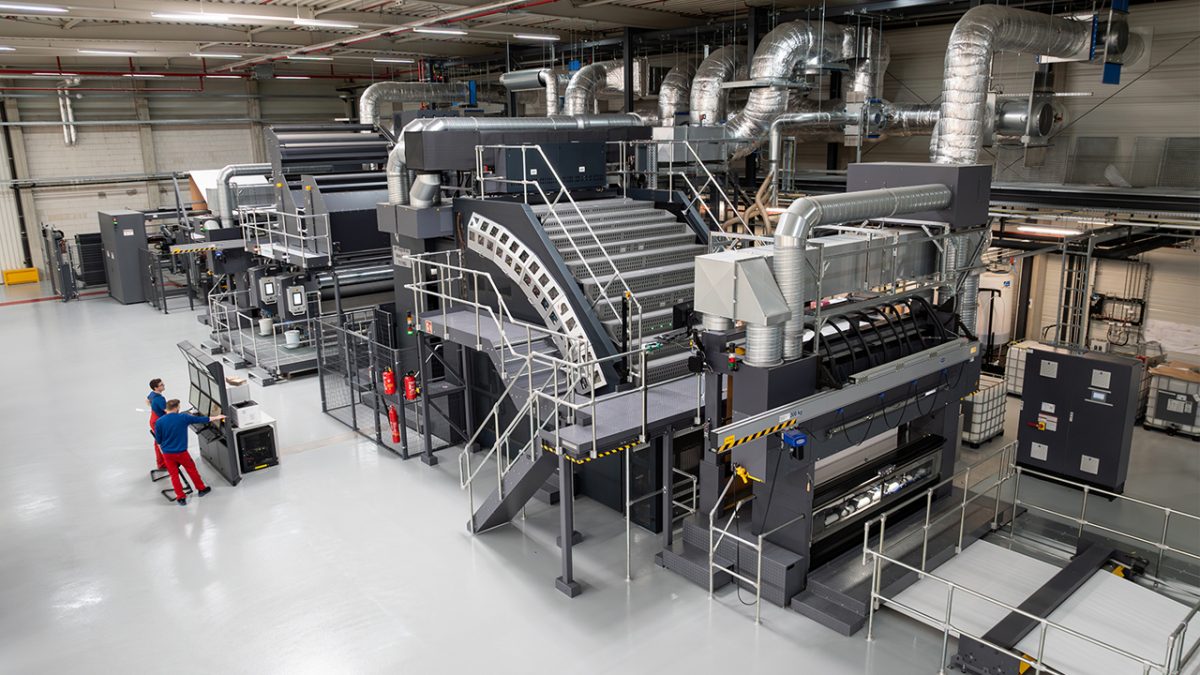

The HP PageWide T1195i press, one of Europe’s most innovative digital printing systems, has been successfully commissioned at the Alzey site over the past few months and was officially opened and inaugurated over three days. Following the successful preview of the new machine for local politicians, economic representatives and journalists from the trade and regional press on the first day, the ceremonial inauguration of the printing press took place the following day, with 150 Thimm customers from the consumer goods sector attending. The opening was rounded off with an internal conference for Thimm sales staff, who were also given a practical insight into the new press and the topic of digital printing. Over all three days, visitors were not only impressed by the innovative system, but above all by the forward-looking strategy pursued by the company, with its consistent focus on digital printing technology.

“We have a clear goal in mind,” emphasised Kornelius Thimm, CEO. “We want to make digital printing compatible for large-scale use and open up further product portfolios. Thimm customers will benefit from even shorter lead times, efficient and sustainable production processes and the flexible design of their print images without minimum order quantities. With digitally printed packaging, we are also contributing to the digitalisation of supply chains, which is becoming increasingly important these days. We are thus consistently advancing our vision of the ‘Internet of Packs’ – the networking of all processes, machines and objects in packaging management, made possible by digitally printed packaging.”

High capacity offering

Thimm claims that new machine at the Alzey site produces a significantly higher capacity of high-quality and sustainable packaging printing than is possible on conventional printing systems. The two additional analog inking systems enable hybrid printing which combines the advantages of digital printing with the possibilities of analog printing such as spot and full-surface varnishing. Another special feature is the position of the HP PageWide T1195i Press in the plant layout: it has been set up and installed directly next to the existing corrugator. This means that it will be possible to forward pre-printed paper webs directly to corrugated board production without any delays due to timings or transport routes.

With the investment, the company is also sending a clear signal for the future and development of the Alzey site – as an employer and as a training company. Family business Thimm is celebrating its 75th anniversary this year. The plant in Alzey was built in 1980 as the third site at that time.

“Our mission at Thimm is to work in partnership with our customers to tackle their current and future challenges, and to offer them innovative and simple solutions – as we have been doing successfully for 75 years. By investing in this new printing press in Alzey, Thimm is once again leading the way as a pioneer in the corrugated cardboard industry. With digital printing, we offer answers to our customers’ logistical, economic and ecological challenges and stand by them as a reliable and innovative partner for a successful future – even and especially in challenging times,” concluded Kornelius Thimm.