Spectrum Lithograph, an ISO Certified carton converter established in 1981, has seen profitable high-end, short to medium runs with Fujifilm’s J Press 720S.

“Our core business is folding cartons,” said Shawn Pereira, VP of Sales and Marketing. “We service the medical and pharma industry, retail and confection markets as well. We wanted to be more competitive within the industry and digital inkjet was the answer.”

Fujifilm says that its production inkjet sheetfed J Press offers the quality and robustness of an offset press and the versatility to handle even the shortest of press runs. Now available in its third generation as the J Press 750S, it is designed to offer the flexibility of a digital platform with the ability to produce personalized variable data work and also eliminate the costs of plates, make readies and the associated labor costs.

“We are able to print on 24pt, with virtually no minimums,” says Shawn. “If a customer wants one box, we can output one box quickly and cost-effectively. Recently I was on the phone with a potential client, he emailed the creative file to me and was en-route to our facility; by the time he walked into our building I had the actual output in-hand to share with him. Needless to say, he is now a customer and it was an easy sale. The J Press is positively impacting our bottom line.”

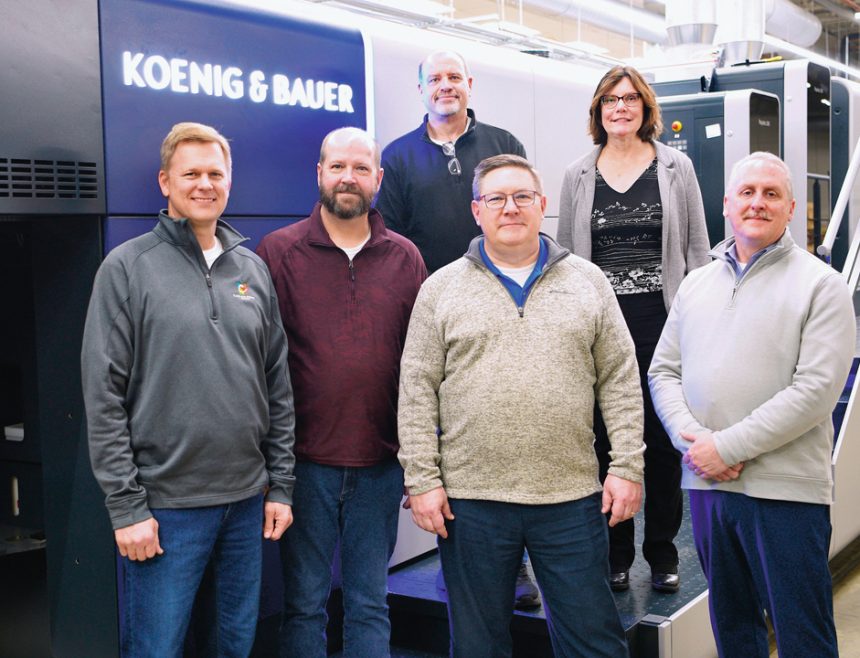

Left to right: Dino and Fernanda Pereira, with son Shawn, alongside the J Press 720S at the Spectrum Lithograph facility in Fremont, California.

Consistency is key

Registration accuracy and color consistency are critical when servicing a well-known, global customer base. “The registration accuracy on the J Press is perfect, which is important,” says Shawn. “The tolerance is tight and the gripper and guide on that press absolutely make a huge difference.”

“The color consistency is flawless,” adds Dino Pereira, CEO, Spectrum Lithograph. “We are able to use our existing Aqueous and UV coatings successfully.” Fujifilm has working relationships with coating manufacturers to develop specific formulations of aqueous coatings to gain outstanding results with both offline and inline coaters.

Within the ever-evolving printing industry, the Pereira’s understand they must adapt to meet customer needs. Quick-turns and shorter runs are the new-normal at Spectrum Lithograph and the J Press has created expanded business opportunities.

“Instead of outputting large runs, our customers are requesting shorter runs because they want to keep inventory levels low with regard to items within their product line-up becoming obsolete,” said Shawn. “Regulations and regional SKUs often change for our customers; so rather than having to discard hundreds of thousands of pre-printed product from inventory, we are able to provide them shorter runs at a lower unit cost, with quick turnarounds. It’s more economical to produce shorter runs on the J Press for our packaging customers.”

Reprints and repeatability

“We output a lot of reprint jobs and the repeatability on the J Press is really much easier compared to offset,” adds Dino. “We are running more jobs on the J Press and fewer jobs on the offset press.”

A second-generation family-owned business based in Fremont, California, Dino opened Spectrum Lithograph in 1981. With 38 years and counting, the Pereira’s operate out of a 25,000 sq ft building, with upwards of 20 full-time employees.

“Spectrum Lithograph is known for delivering a high level of quality and the J Press is allowing us to achieve very impressive output, efficiently and effectively, for all of our customers,” concludes Dino.