This year has been a challenge, to say the least! With the global pandemic and restrictive measures that governments around the world have had to take to try and bring COVID-19 under control, quite understandably, expos and conferences all around the world have been either cancelled or postponed to a later date. This leaves machinery manufacturers with a dilemma, especially those who had machinery developed specifically for launch at leading industry events.

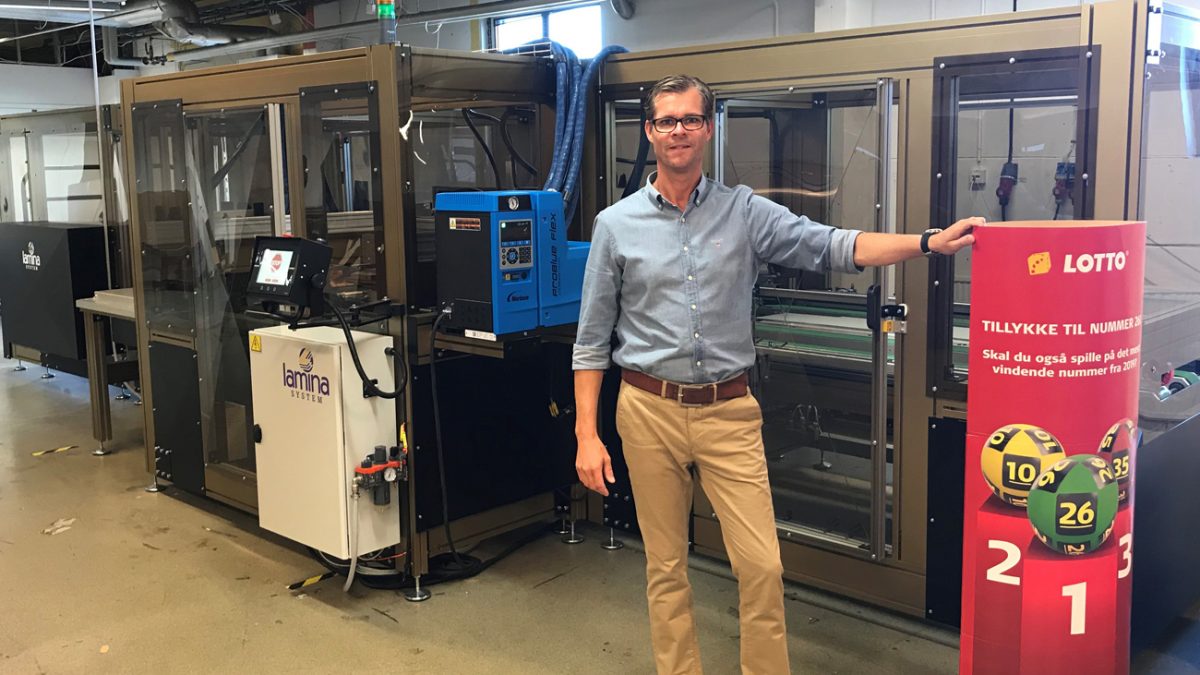

Swedish machine designer and manufacturer, Lamina System, was one of those who had a big development that they wanted to showcase to the global graphic arts and packaging industries, particularly looking forward to Drupa. “When the announcement was made, we were naturally disappointed, as we had a new machine to unveil to the global audience,” explains Peter Hjalmarsson, Managing Director. “We had spent many months designing a new system to help speed up the assembly of POS displays made of corrugated board. We were all set to launch the Popupline at Drupa, but with the postponement of the event, we had to find the first customer and try to promote the machine by way of video and webinar sessions. Fortunately, we managed to secure a customer who was abut 250km south of our factory in Boras. We installed the brand new machine recently.”

Display Specialist

Based in the town of Landskrona in Sweden, about 45km north of Malmo and on the coast of the Öresund straights, ML Display is a privately owned POS and short run packaging specialist.

Founded in 2007, the company employs 35 people and produces a wide range of POS materials for grocery and specialist retailers. The displays are usually made of corrugated and solidboard, but often include other materials.

“Always with the customer in mind, we have tried to ensure we always have the latest and most modern machinery at our disposal,” says Jesper Ljunggren, Local Manager at ML Display AB. “With new machinery, we are always focussed on product development, speed of turnaround and creating the most cost effective display solutions for our customers.”

He continues, “Since our founding, we have worked according to the motto that quality and service means a good product and fast delivery. We own patents on special solutions, we have a machine park that is of today’s highest quality that includes both digital printing and fully automatic cutting tables. But around all this, we have one of the industry’s most experienced teams, all experts in their specific parts.”

New Design

The Popupline is an assembling line for standee POS displays. The machine automatically handles the components and assembles and glues them, with the completed display being exited from the machine in a speedy process.

“This new line is an automated production line for mounting the display,” explains Hjalmarsson. “The idea is that the product should be 100% recyclable with as minimal an environmental impact as possible. In order to achieve this goal, all elements of these displays consist of fibre-based materials. Since the intended life of the finished product is relatively short, the possibility of appropriate recycling is significant.”

Growing, growing

“As part of a strategy for continued growth, ordering Laminas Systems’ newly developed fully automatic Popupline was an obvious step,” concludes Ljunggren. “We are very pleased with the machine and the installation was smooth and efficient, even with lock-down measures in place. Overall, we believe we have chosen a machine that will allow us to take ML Display to the next level. Thanks Lamina – we are really impressed.”