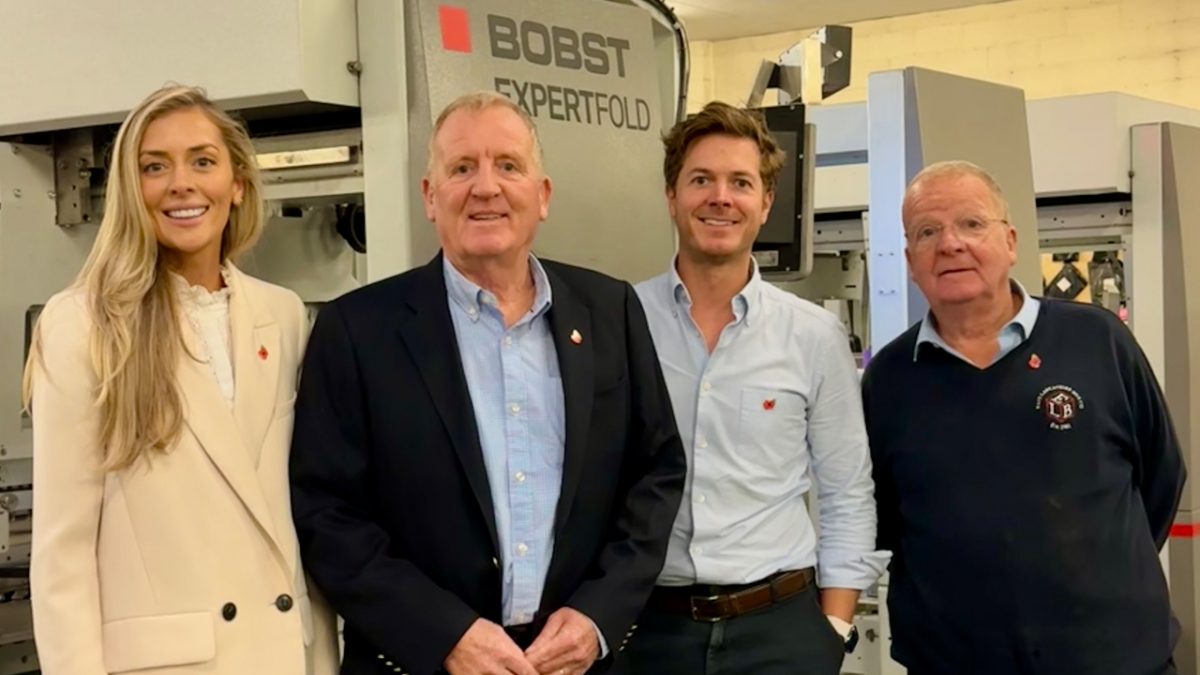

Above, left to right: Amy, Peter, David and Nick Ingham.

East Lancashire Box Co have come a long way since they began as a shoebox maker set up by two brothers in 1981 – and yet they remain just as much an independent family company now as it was then.

“Today, what you see on the supermarket shelves is what we’re all about,” says Peter Ingham, Sales Director.

During the pandemic, the food industry’s demand for Shelf Ready Packaging exploded, and – as a result – East Lancashire Box Co came out of the pandemic stronger than they were before it started. As costs continue to rise due to the cost-of-living crisis, inflation, and supply chain issues, the company has proven the only way to offset these rising costs is to be faster and more efficient while maintaining its high quality.

“We’ve been able to hold on to the business we picked up during COVID,” says Peter. “It’s entirely down to the quality of service we provide, and the speed at which we provide it. That’s why efficiency underpins every decision we make.”

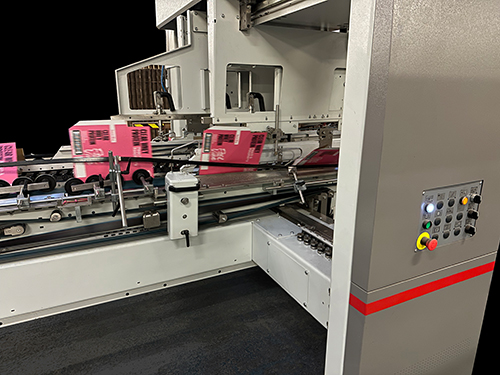

The company recently installed its third BOBST EXPERTFOLD folder-gluer – this gluer has greatly increased the speed of production and added much-needed capacity.

“The extra gluing capacity that the new Expertfold folder gluer has given us enables us to not only look for new business but also to offer our confidential gluing service to other packaging companies with no gluing capability or to the larger integrated corrugated companies where smaller gluing volumes become a hassle to produce,” says Peter.

This gluer is the seventh Bobst machine to be installed as the company continues to expand.

It now operates from two sites — high-quality printing, die-cutting, and quality control all take place at the 22,500 sq ft Rishton site, while the gluing and finishing take place a mile down the road at the 16,000 sq ft Clayton-Le-Moors facility.

Every step of their manufacturing process is handled by seasoned, experienced staff, run on reliable machinery that delivers quality, repeatable results, all managed by brothers Nick and Peter, and two of their children David and Amy.

Peter – along with his daughter Amy – focuses on sales and customer service, while his brother, Nick, and his son David look after the production side of the business. The pair appear to have mastered the art of succession without any drama.

They now employ 58 people working at their two sites – 20 of these 58 employees have worked at the company for over 25 years. Many are related; George Lockhart who achieved the 25-year mark in 2022 has had 18 off his family work for the company and Susan Thompson who achieved the same milestone in 2022 has had 22 of her family work for the company over her 25 years. They pride themselves on being a true family business.

Peter and Nick have seen the company grow into a highly respected outfit within the UK’s packaging industry. “Many of our customers have been with us for over 20 years,” Peter says. “Our philosophy has been to look after what we have, and then growth can then be controlled and selective.

“We keep very little stock on-site,” he continues. “What we print and cut today is glued tomorrow and is out of the door the following day. It’s a lean process that is more efficient than Just in Time. It relies and succeeds on unbeatable communications with our customers.”

The company has developed a self-sufficiency that means, all enquiries, samples and quotations are personally responded to by a member of the family within 24 hours. Artwork and colour swatches are created in-house, which speeds up the process of getting approval for a new or amended job. “With first-time orders, we aim to deliver within 10 working days of everything being signed off,” Peter says. “For repeat orders, we aim for five working days depending on board availability. All orders are manufactured on site on our own state-of-the-art printers, die-cutters and gluers.”

Deliveries are made by the company’s own vehicles, driven by experienced drivers who have worked for the company for a number of years and who know and respect their customers. Every step, from production to delivery, is made with this kind of personal touch in mind.

This caring approach extends to the planet, too. East Lancashire Box Co is BRC accredited and is in the process of applying for FSC accreditation, showing how the business continues to evolve to meet market demands for sustainability as it grows.

All waste cardboard is baled and recycled, while much of the board it uses is two-thirds recycled and one-third virgin fibre and is 100% recyclable. All their corrugated board is manufactured by a FSC accredited corrugated board supplier and 70% of its inks are biodegradable and made with vegetable oils.

When East Lancashire Box was founded more than 40 years ago, packaging was a means of getting your goods to store, today packaging has become a major tool in displaying and selling your product.

In this ever-changing world, this family business has learnt how to change with the times.