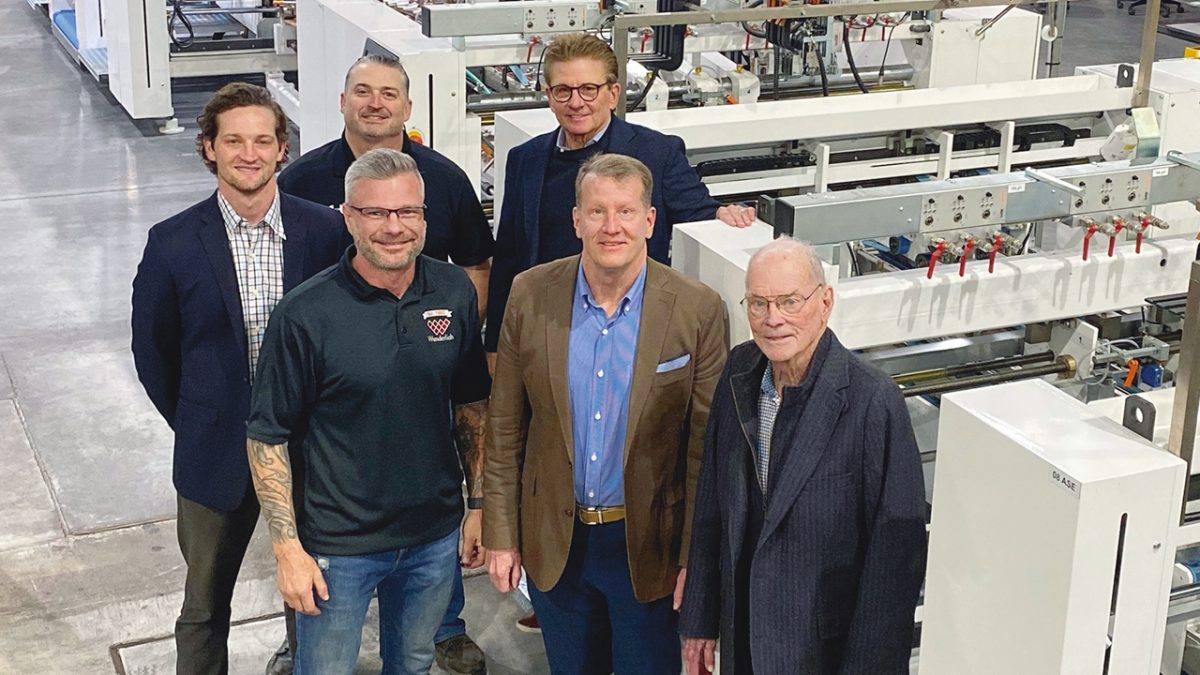

Back row, left to right: Steve Dybus, Jr., Jeremy Touchette and Steve Dybus. Front row, left to right: Roman Cannon, Robert Wunderlich, Jr. and Robert Wunderlich, Sr.

Like many multi-generational family businesses, Wunderlich Fibre Box Company traces its roots back a long way; 1860 in fact, when Chas. Wunderlich Cooperage Company was founded, manufacturing wooden barrels in St Louis, Missouri. Seventy years later in 1930, the company expanded its production capabilities and started making corrugated packaging; then, in 1960, the company ceased making wooden barrels and focused 100% on corrugated. The rest, as they say, is history.

More than 164 years into its operation, Wunderlich remains a family business. Currently, the fourth-generation representative is Robert Wunderlich, Sr. while the fifth generation is represented by Robert Wunderlich, Jr. Leading the company is Steve Dybus. And upholding the same tradition, Steve’s son, Steve Dybus, Jr. (the grandson of Robert Wunderlich, Sr.) is the most recent generation to join the company after completing the packaging program at Clemson University and gaining valuable experience for several years at another independent company.

With a team of 75 members that serves a diverse customer base across the United States, this independent sheet plant maintains strict standards of quality with annual Third-Party GMP and OSHA SHARP certifications. While about 65% of its annual production is for corrugated packaging, the company’s point of purchase display business has steadily increased each year. This growth prompted Wunderlich to prioritize new equipment investments to enhance production capabilities.

Equipment wins business

“Investment has always been part of the success of Wunderlich over the generations, the ability to spot an opportunity and react,” explains Steve Dybus, President. “The last serious investment project was about 10 or 12 years ago, and that resulted in quite a lot of new business being won.”

While Wunderlich’s machinery park is already comprehensive (the company is running two flexo folder gluers, a four-color rotary die-cutter, a flatbed die-cutter and a litho-laminator), Dybus saw a need for a powerful specialty-folder gluer to keep up with the growing demand for point of purchase displays.

Power of Associations

“Our latest investment project has seen us install a new specialty gluer, with bundler, conveyor and load former,” adds Dybus. “Our existing gluer was starting to reach end of life and we started to look at what was available in the market. Through the excellent networking we have always enjoyed via AICC, we had a conversation about new gluers with John Kelley at Dusobox down in Orlando. John had recently installed a new machine from Europe and suggested we come down and have a look – naturally, we jumped at the opportunity.”

He continues, “We had some board shipped down to Dusobox and after the AICC Spring Meeting in Miami in April 2023, John kindly let us run trials on his new JD BoxR, which ran really well. We were convinced this was the machine for us, having spent time with Doeke Holtrop, owner of JD Engineers, at the Dusobox facility.”

Wunderlich placed the order for the machine in the late spring of 2023 and by September, the machine was ready for inspection at JD Engineer’s facility in the Netherlands. “We traveled to see the machine prior to sign-off, where we were also able to see it running,” says Dybus. “The team at JD showed us the machine in action at their facility and we continued to be hugely impressed by the incredible set-up times and the overall ease of use.”

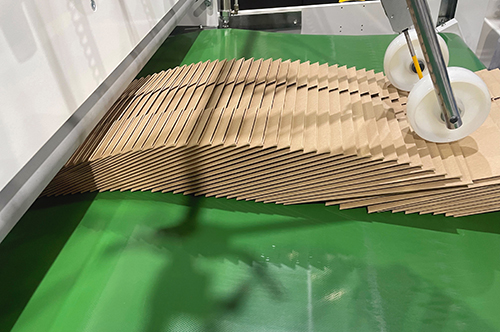

Once the Wunderlich team was satisfied, the Tanabe JD BoxR was then put in containers and shipped to St Louis. By Christmas 2023, the machine was installed and ready to run. With an integrated bundle tier from Signode, conveyors from ACS and a load former from AG Stacker, the line was fully operational by the end of February, achieving great results from day one.

The gluer at Wunderlich is a 67” (1700mm) wide machine, with the inner measurements of a 57” (1450mm) machine. This means the transport guides have the size of a 57” (1450mm), allowing the customer to run a wide range of box sizes and styles (maximum size of a 67” (1700mm) and minimum size of a 57” (1450mm)).

The machine is equipped with a defect ejection unit and glue is controlled by the integrated JD Engineers Glue Controller for easy setup calculated by the JD Box Editor; this means that no standalone glue controller or interface is necessary. The JD Glue Controller can handle all brands of glue guns, pumps and glue detection sensors, irrespective of brand. The machine at Wunderlich is also equipped with a diagonal folding control and a length control system, that controls the parameters of every box.

Double output

“We are really excited by the opportunities this new specialty gluer line offers Wunderlich,” says Dybus. “It gives us effectively double the output of our previous machine, with lots of additional value-added features, such as defective box ejector and its ability to run solidboard and corrugated board. Being able to run solidboard allows us to open more avenues for sales to new customers and the fact it can run 6-corner boxes is also a great advantage for us moving forward. Add in that it runs with fewer operators means we can add more shifts in the gluing department, which is a real win-win for us.”

Dybus concludes, “The team at JD have been superb throughout the whole process, being super attentive to our questions and training requirements. We are proud to be part of a growing group of U.S. converters running the JD BoxR. It really is a great machine.”