Digital preprint with roll-fed digital presses offers box-makers new opportunities to take out cost and time in the printing process and improve the efficiency of downstream processes. Efficient production of jobs shorter than one roll is possible when analog plates and make-ready time are eliminated. This addresses the customer trend for short runs. Fast turnaround time and just-in-time production delivers supply chain agility to brands, eliminating the need for inventory.

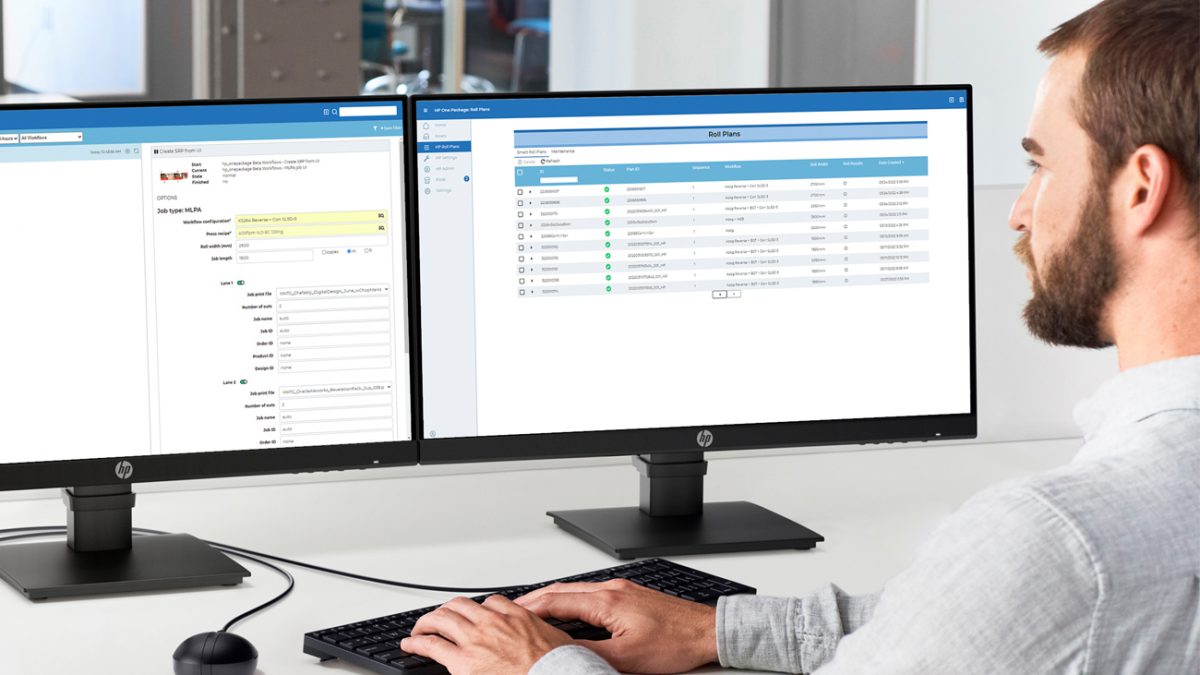

Because digital print uses no plates, it is possible switch from one artwork to the next without stopping. This means that a roll can contain multiple artworks or orders. The challenge, though, is to introduce this multi-job roll into the production system without negatively impacting downstream processes. The digital printing process needs to take place under the control of the existing factory management and planning systems. Other processes within the production system may need to be informed about the digital rolls in order to handle them efficiently. HP has now released a software solution that addresses these issues – it is called One Package, the integrated HP workflow software for automating production and improving site efficiency.

Success in Italy

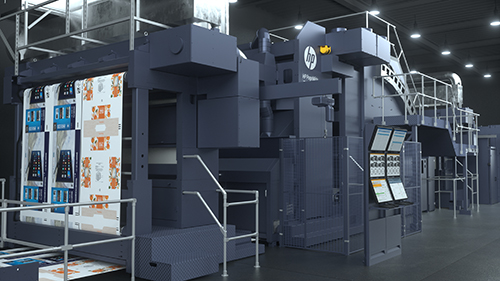

LIC Packaging Spa, a leading European manufacturer of consumer packaging and display solutions, installed a high-volume inkjet HP PageWide T1190 Press at its facility in Verolanuova, Brescia, in 2021. The investment in the six-colour digital press, a 2.8m wide solution running at 305m per minute, made LIC the first converter in Europe to own HP corrugated packaging presses for both preprint and post-print production processes, after taking the lead with HP PageWide C500 digital corrugated press, in 2018.

Next Step

LIC is now the first HP customer to install the HP One Package Preprint Production Module. The HP One Package solution acts like a hub that connects the HP T1190 Press to every component in LIC’s plant and planning system. HP One Package makes it easy to produce complex rolls with multiple short orders by automating the steps to build a print-ready job and submit this to the press. Automation improves efficiency and eliminates errors.

The process starts with a PDF artwork prepared by LIC’s pre-press team using Hybrid Software PackZ tools. Next, they receive a plan from LIC’s planning system, which details all the jobs which need to be combined on one roll. One Package prepares job tickets for the T1190 press that define the sequence of the jobs on the roll, production marks, separators and marks to control the corrugator. A ‘Roll Results’ table is generated after printing which details the exact quantities of each product which have been produced.

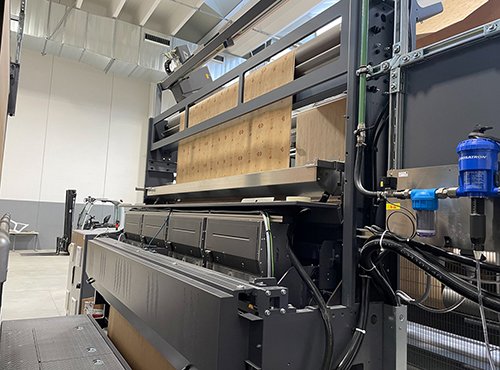

Both of LIC’s corrugators have been fitted with E+L’s SmartLine system. Special marks placed by One Package inform the SmartLine system when the corrugator should execute an order change. The HP T1190’s Multi-Lane Print Architecture enables planners to combine the efficiency of multi-knife corrugating with digital preprint.

One Package also connects to LIC’s iPQ-Check full web inspection system from BST Group. It sets up the inspection system so that it knows how to inspect multiple jobs on the roll without stopping. If defective print is identified, this is passed back to One Package and the Roll results table is updated.

HP One Package is built on top of Hybrid Software’s powerful Cloudflow workflow automation system which also enables LIC to automate and streamline many of their upstream preprint processes. By installing and testing this complete workflow ecosystem right from the outset, LIC is positioning itself for rapid growth of print volume.

Good Results Already

“Unlike earlier users of the press, we benefited from having HP One Package installed right from the start and we are now using it to prepare all our jobs for printing,” says Piero Bertoldo (pictured left), President, LIC Packaging SpA. “We now have complete automation: our planning system creates the roll plan and One Package automatically adds all the marks and steps across the web, before submitting the job to the T1190 Press.”

“Unlike earlier users of the press, we benefited from having HP One Package installed right from the start and we are now using it to prepare all our jobs for printing,” says Piero Bertoldo (pictured left), President, LIC Packaging SpA. “We now have complete automation: our planning system creates the roll plan and One Package automatically adds all the marks and steps across the web, before submitting the job to the T1190 Press.”

Bertoldo concludes, “We were happy that HP chose to base One Package on Hybrid’s software solution, because we are already familiar with PackZ and Cloudflow and find them to be friendly tools. We have really hit the ground running with the T1190 and One Package and continue to cement our position as one of Europe’s leading digital print providers for corrugated packaging.”