Golden West Packaging Group, the West Coast-based packaging converter, has launched a new digital corrugated solution that is allowing its wine and beverage industry customers to adopt a new operating model based on fast speed-to-market and improved sustainability.

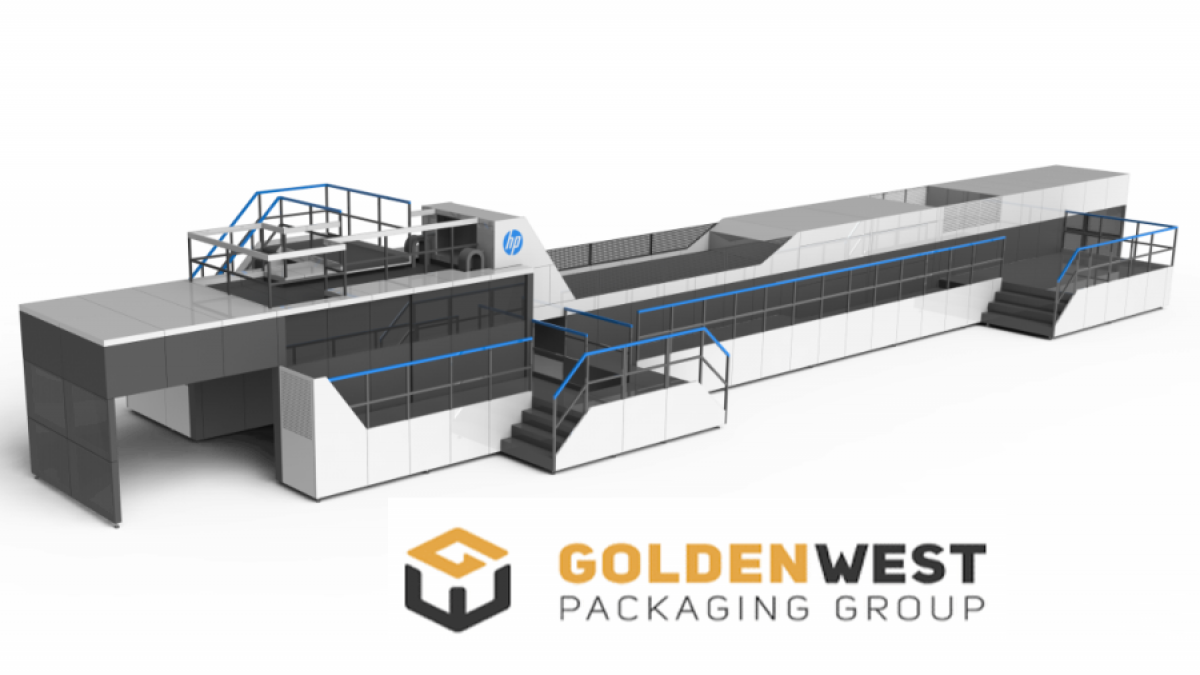

Strategically located in California’s wine country, an HP PageWide C500 digital corrugated press is operating in GWPG’s Livermore site. The high-volume, water-based digital solution is delivering new production agility, enabling GWPG to react quickly to fulfill packaging orders for key customers in the wine and spirits market segment. GWPG also supplies packaging for agriculture and specialty foods, including a wide variety of products that require agility and speed to market.

“The HP C500 is changing the rules of the game with substantially faster package supply. Our customers now have new freedom and the flexibility to do what they want, when they want it,” said Brian Fellows, VP of Sales and Director of Digital at Golden West Packaging Group. “Today, during the pandemic, the demand for fast turnaround combined with production flexibility provides our customers the options they need for an ever-changing marketplace.”

Wide Range of Products

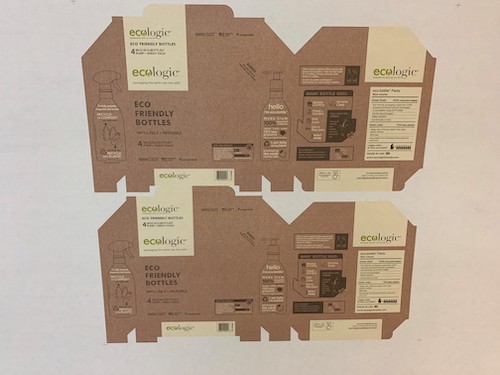

GWPG supplies a wide range of digitally printed products including corrugated cases, trays, pallet skirts, case sleeves, headers, and displays to the wine and food industry. GWPG also supplies a wide variety of custom boxes for computers including HP. GWPG supplies the West Coast, Mexico and far beyond.

According to Fellows, lead times using the C500 solution can be reduced to 10 working days or fewer, compared to several weeks using traditional methods. In addition, by leveraging their range of digital solutions, GWPG can fulfill orders as small as a quantity of one to millions.

Direct-to-consumer, subscription and on-line purchases including home delivery, especially for the holiday season, are also driving demand for flexibility in printing that can be fulfilled by digitally printed solutions, noted Fellows.

The GWPG group includes over 20 creative and structural designers, making it easy for brands to transition to digital. It offers award-winning, in-house graphic design and structural engineering to help customers develop unique and creative solutions for digital packaging.

GWPG has also achieved G7 certification, which ensures accurate color matching across print platforms and our affiliated businesses. “This allows us the flexibility to react to any customer need,” said Fellows. The HP PageWide C500 Press quality is also comparable and interchangeable with any corrugated print method, delivering sharp text and barcodes, smooth tone transitions, and vivid colors.

Water-based inks enhance sustainability scorecard

The addition of the C500 to GWPG is adding a further benefit for its sustainability-conscious consumers. The C500 uses true water-based HP inks that can be used safely for food applications including without adding another contact layer. HP’s water-based inks are odorless and free of UV-reactive chemistries and can comply with even the most stringent global food safety regulations, including Nestlé guidance and Swiss Ordinance.

GWPG’s 250,000 sq ft site is also 90% solar-powered uses a closed-loop water system so they don’t put any wastewater into the local ecosystem. “This especially resonates with eco-conscious wine and food suppliers,” according to Fellows.

The addition of the industrial-scale HP PageWide C500 Press builds on Golden West’s experience with high-value corrugated display and high-graphic retail packaging production using its fleet of HP Scitex 15500, 11000 and FB700 presses.