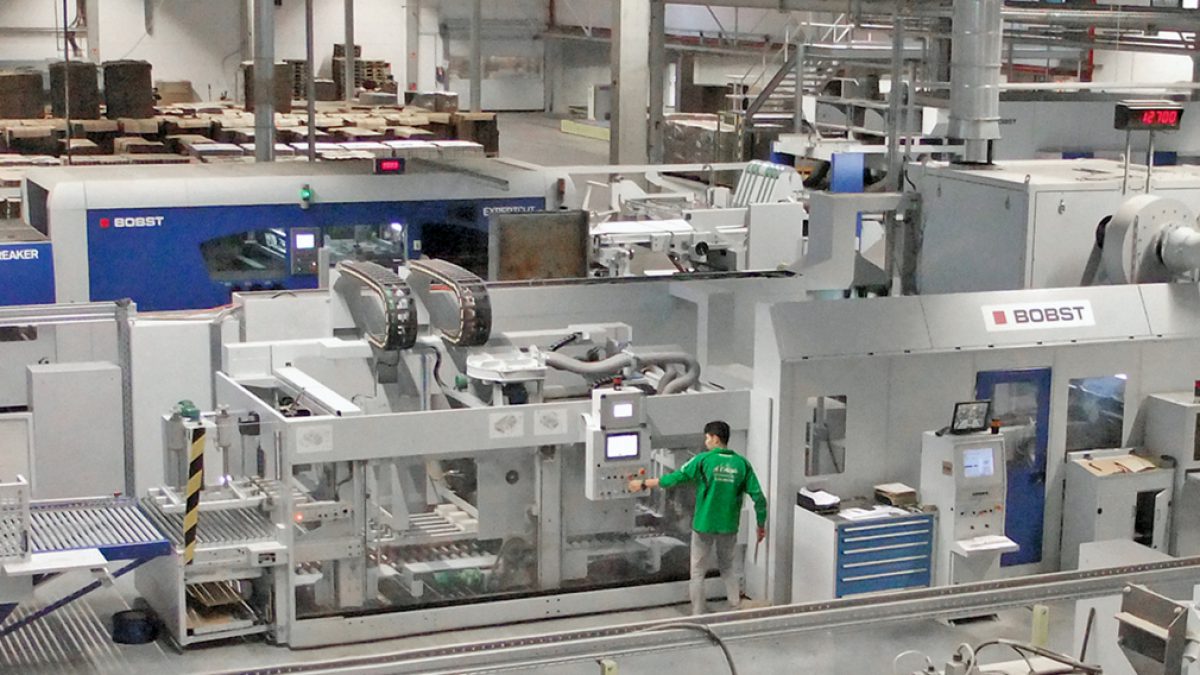

With the size of its new manufacturing facility near Pirmasens in Germany and the equipment installed within it, G & G Preißer is setting new standards in the European corrugated market. To do this, the company commissioned four new converting machines from BOBST. It only took a few months for the machines – Expertline 1.6 with five Flexo 160-Vision print units and hot air intermediate dryers; Masterfold 230; FFG 1636 NT and Miniline FFG 618 Quatro – to be running at full capacity, three shifts a day.

G & G also upgraded a Midline FFG 924 NT with a pre-feeder and an automatic palletisation system and has already ordered another Expertline 1.6 and an additional Expertfold 165. They will be delivered and installed during 2019. G & G Preißer will then have more than seven converting machines from the same supplier in its new plant. They will be used to manufacture packaging, primarily for customers in the food, personal care and cosmetics industries. The production process takes place in a completely clean environment.

“Use of this innovative technology fulfils any requirements our customers may have,” stated Tobias Preißer, who manages the company along with his brother Christof. The three Inliners are still covering about 80% of the production volume. However, the demand from customers for high quality packaging, such as multi-colour printed and varnished trays or shelf packaging, is growing steadily, thus the reason for the high quality printing and die-cutting line.

Christof Preißer adds, “We cannot accommodate our customers with price reductions. However, we can convince them with the quality we are getting from our new machines. The flatbed die-cutter delivers high-quality creasing and cutting and the tolerances for the GAPs and slots are tighter. The nicks can also be smaller or even dispensed with completely. The process also improves the quality of the flatbed die-cut trays and packaging. There is also no waste between the sheets. This is all advantageous for the customer’s filling processes.”

Colour Counts

Using its three Inliners, G & G is flexible in the sheet format of the packaging to be manufactured and can pull out all the stops when it comes to colour. While the FFG 924 NT covers all formats, with a length of between 600 and 2,490mm, the FFG 618 Quatro processes sheet lengths of 385 to 1,880mm and the FFG 1636 NT processes sheet lengths of 700 to 3,690mm.

The FFG 618 Quatro is fitted with dryers and can deliver high-quality print images on sheets at high production speeds, even with four colours. The two other Inliners each have two print units.

To avoid downtime as much as possible, G & G uses the preventive ‘Maintenance Plus’ programme for all of its Bobst machines. In case there should be an issue, a service technician can remotely access the machine over ‘Helpline Plus’ and solve problems quickly. In the future, G & G plans to tie the machines to the innovative ‘Connected Services’, with the goal of analysing machine and process data and to gain optimisation potentials from the results.

In 2018, G & G converted about 85 million sqm of corrugated board – for 2019, the company is planning to process a volume of 110 million sqm. Currently, 1,600 pallets of finished product leave the plant every day. Only ten years ago, the annual volume was just 450,000 sqm. “With its high performance and reliability, the technology from Bobst is the ideal support for our growth,” said Tobias Preißer. “We plan to continue our success story.”

Left to right: G & G Managing Directors Christof and Tobias Preißer with Richard Perner from Bobst Meerbusch.