The growth for Cartonnage Lammerant continues, as this leading Belgian corrugated packaging manufacturer has now completed the installation of a new 2.8m corrugator from BHS Corrugated, along with an Intralogistics system for the automatic transfer of paper reels around the facility by iShuttle carts.

This was, however, not a straightforward installation. It was not a case of take out the old machine and install a new one; instead, Lammerant worked with BHS Corrugated in a phased approach, that would see individual machine units taken out and replaced over the course of three stages.

“In 2019, we knew we need to upgrade our corrugator, as our previous machine was starting to reach its limits, working at an average speed of around 220m per min, which was not enough for us,” explains Mathias Lammerant. “We actually did some upgrades to that machine, but within a year, we agreed with BHS Corrugated that the best solution for us was to put in a new machine. However, we did not have the space, nor enough openings in our production schedule to allow us a significant period with no corrugated production. So we worked up a plan that we would roll out over 18 months or so, a plan which would result in a new line – and all with a maximum of 20 days at any one time without the corrugator running.”

Mathias Lammerant and his family were also keeping a close eye on the operators, as retention of skilled operators is one of the most pressing issues that the industry faces today. “By undertaking the project in phases meant we could keep the machine running, which meant our operators were busy, and effectively learning the new technology while they were working. In addition, we specified a highly automated line, so that operators had the latest technical solutions at their fingertips,” he adds.

The first move came in April 2021, when they took out the old single facer and installed a Modul Facer MF-A together with two new splicers of the latest generation and the new Roll Stand generation RS-A, which allows fully automatic paper roll supply and pick up by BHS Intralogistics. Quality improvement was seen straight away. Then the new triplex dry-end and the second MF-A were installed in the Summer. Moving a complete triplex dry-end out of the existing building and installing and commissioning a new one in the same place in less than three weeks was a tremendous challenge. Finally, about 12 months after the dry-end came the double facer – that was July 2022. But now look at the dates – the middle of the pandemic!

In order to fulfill Lammerant’s needs for a high speed production of high quality board, the dry-end has the BHS Hyperblade which allows them to do the order changes up to 400m/min. Speed fluctuation at dry-end order change is minimised which allows a continuous high quality board production.

Another feature of the dry-end is the BHS Zero Defect System 2.0 which is installed after the rotary shear. With its microwave sensors, it detects any type of board defects and evacuates automatically at full line speed at the cut-off. Any type of board defects, regardless whether it comes from the single facer or the glue unit, are taken out at the earliest possible point before they create additional productivity issues in the converting area. This dry-end brought a significant productivity increase of about 15% compared to the old corrugator.

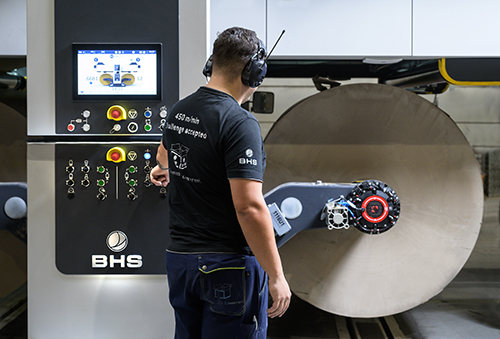

With this final stage of the corrugator exchange finally completed, the maximum line speed could be increased up to 450m/min, and a tremendous productivity increase of 20% was achieved relatively soon after the installation.

Autonomous Movement

Lammerant also became the first site within Europe for a BHS Intralogistics solution for automatic paper roll supply of a corrugator. In the Christmas period 2022/23, the installation and commissioning of the BHS Intralogistics system completed the path of expansion and automatisation that Lammerant and BHS had envisioned exactly two years earlier.

The roll supply by the BHS iShuttles has not only the advantage of further automatisation, but it also eliminates any forklift traffic in the area where the operators are moving. “It is a great solution for us, as we could implement it pretty quickly, with no need for lots of groundworks,” says Mathias Lammerant. “This system, when fully operational, will allow a bigger buffer of reels in front of the corrugator, which is just what we need now we have a machine that can run at 450m/min.”

Taking Stock

“It was a tough project to manage, as we were totally restricted by the pandemic regulations,” continues Mathias Lammerant. “And to top it all off, we also installed a BOBST 924 and a Cuir flexo printer with Dücker pre-feeder – it was a very tough time, but with work from all the suppliers, we managed it.”

But that’s not it. “Although this is the largest part of the latest investment cycle, we are not finished,” concludes Lammerant. “We have just completed a 25,000 pallet high rack storage system, which went on-line in June and we continue our work with Seemi for materials handling, so that we can remove the need for any forklifts inside the corrugator bay and converting hall. In September we take delivery of another BOBST line – this time, a four colour 8.20 flexo folder gluer. The extra capacity that this new corrugator gives us means we need even more converting equipment to ensure we are able to convert all the board this new line will produce!”

Established in 1964 by Roger Lammerant and his wife in the small town of Thulin in the Montoise region of Belgium, the company started out producing solidboard boxes for a range of industries, such as glassware, shoes and poultry. But about five years later, the company started to look at moving away from the production of solidboard packaging and started to look at producing corrugated packaging. Following a move into a new facility in the town of Leuze-en-Hainaut in 1973, the company started to produce more and more corrugated solutions for a growing customer base. Sadly, in 1977, the founder died and his wife and two sons, Etienne and his brother, took over the running of the business.

Decades of investment followed, including the installation of a 2.8m BHS Corrugated line in 2003, being the first of its type in Belgium. Behind this installation then followed the roll out of a series of flexo converting lines, which has resulted in today’s machine park – home to no fewer than 11 flexo converting lines, the majority of which are from BOBST.

The family business was fully taken over by Etienne – and his son, Mathias, joined the company in 2010. A few years later, Etienne’s daughter and her husband joined the management of the company, which is now one of the leading privately owned corrugated producers in Belgium with a diverse range of customers, supplying businesses throughout the region as well as neighbouring countries. Generating over €55m in sales, the company operates from a 55,000sqm site with 120 people.