A history of successful operation, enhanced quality and cost saving realised from their initial Dicar Equalizer™ installation, simplified Smurfit Kappa Germersheim’s decision to install a new (and first for the European market) Dicar Equalizer™ G4 with Snap Sleeve™ split bearings on their BGM 10/24 Inliner.

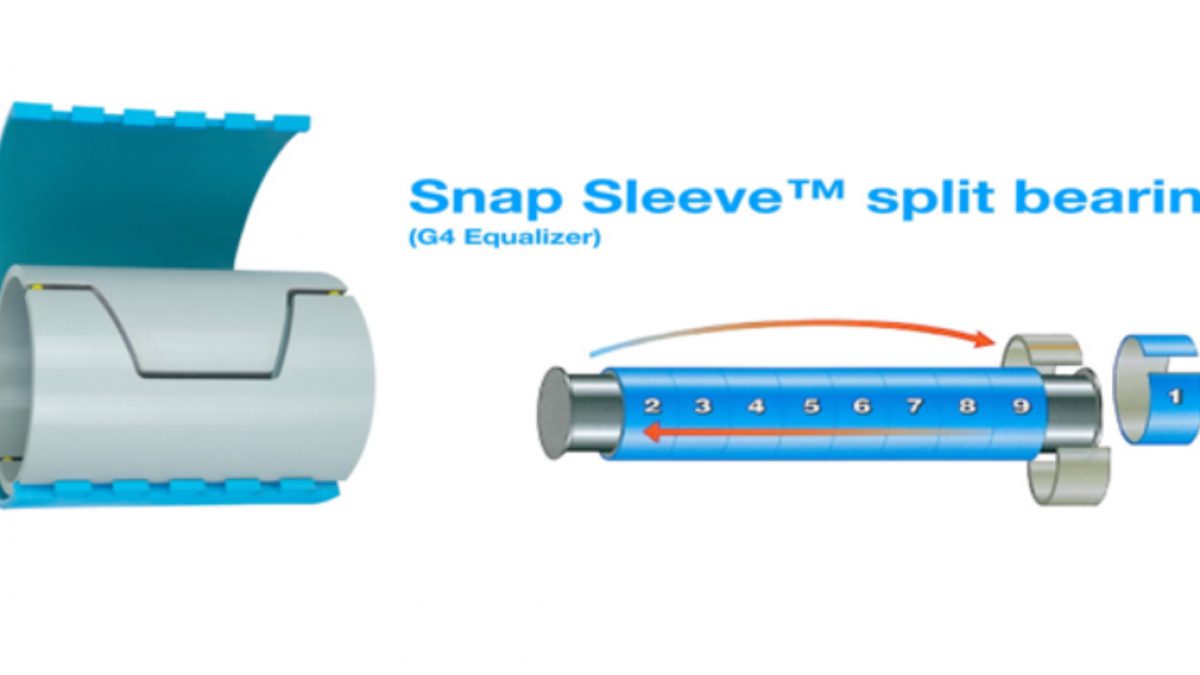

The latest version of Dicar’s popular Equalizer™ rotary die-cutter anvil system, Equalizer G4 uses Dicar’s patented Snap Sleeve™ ‘split bearing’ design to provide new levels of ease-of-use and efficiency to the die cutting station.

The ‘split bearing’ design accommodates thermal expansion to maintain consistent cover mounting. Its special shape ensures each single segment is securely held in place on the cylinder during installation, therefore making mounting easier than ever before. Its ease of use and innovative technology leads to perfect wear of anvil covers, greater production speed, increased production quality and enhanced efficiency.

Norbert Pflug, Die-cutting Department Manager at Smurfit Kappa Germersheim explains, “Some years ago, we set out to optimise the existing bearing system on our Texo rotary die-cutter which was designed for re-vulcanisation. After our research and cost saving calculations, it was decided we would replace the existing OEM bearing system with a Dicar Equalizer System with a basic bearing and separate anvil covers. In retrospect the die-cutting accuracy was significantly optimised and tens of thousands of Euros were saved on anvil covers through using the Equalizer.”

Following the positive results on the Texo, Pflug recently took on a project to optimise the existing bearing system on their BGM 10/24 Inliner as well. The quality enhancement and cost saving advantages of a retrofit convinced Peter Schöpp, Smurfit Kappa’s Production Manager at the Germersheim site and the decision was made to install Dicar’s new Equalizer G4 SnapSleeve system. This will be the first of the new innovative technology to be installed in the European market and outside the USA. The new SnapSleeve system was successfully installed and started up in mid-September 2018.

Schöpp says, “Of course we were interested in the new SnapSleeve system and were finally convinced. Crucial to our decision to replace our existing system with Dicar’s latest anvil covers was the much lower cost of the covers per set and their instant availability. Prior to the installation of the Dicar Equalizer Snap Sleeve system, the covers had to be re-vulcanised and that is a very expensive and time-consuming process. The many years of positive experience we have had with Dicar made the decision to invest in this new system much easier.”

Left to right: Andre Angermeir, (Dicar BV), Peter Schöpp, Production Manager and Norbert Pflug, Die cutting deparment.