Founded over 25 years ago, Derwent Displays has invested more than £1.75m in the last two years to underpin its strategy of using the latest technology to continue its growth, while enhancing customer service. Part of this growth strategy is to develop new market segments beyond its already expansive reach that includes design & prototyping, print and finishing, in-house assembly, packaging and project delivery.

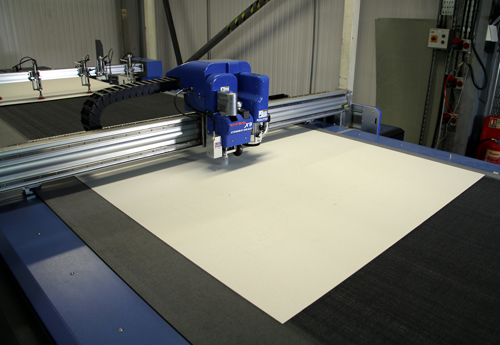

The investment program has seen the arrival of a FujiFilm Onset X2 digital printer and a DYSS X9-1630C Combo Head digital cutter from AG/CAD. The Denby-based company installed the Onset X2 printer with a robotic arm unloading system and similarly, the DYSS X9-1630C incorporates sheet handling automation. Commenting upon the investment, Derwent Displays Commercial Director, Paul White says, “The display industry is competitive and the demand for ever faster prototypes and samples with rapid turnaround times can be the difference between winning and losing business. Both the Onset X2 and the DYSS X9-1630C are making a huge difference by creating improved response times, flexibility and of course bringing in new business.”

With an existing digital cutter running flat out on two-shifts, Derwent needed additional capacity, as well as further capability in terms of handling a wider variety of substrates. “We cut a lot of paper-based corrugated, display boards and plastic corrugated, but more frequently we are being faced with the prospect of cutting boards up to 10mm thick. Anything above 5-6mm was beyond the capability of our existing machine. It is also too thick for die-cutting with standard cutting formes. We are increasingly asked to quote for jobs that require the cutting of Di-bond, Foamalite and Polypropylene. The increasing market diversity meant we needed to look for a machine able to handle this sort of work as well as our bread and butter work,” says White.

Paul White with the DYSS from AG/CAD

Why the DYSS?

The 30 employee business investigated the marketplace and the DYSS machine was chosen for a number of reasons. With a specific set of demands, the DYSS X9-1630C Combo Head machine was selected for its versatility with its variety of tools for heavy duty cutting, creasing, V-cutting , kiss-cutting and a powerful routing spindle that is perfect for processing more diverse rigid material types and thicknesses with impressive speed, precision and edge finish. Equally important was the synergy between the DYSS and Kasemake CAD software, as Derwent was already utilising the CAD software to drive its existing cutting table and design studio.

With automation being a major element of the business strategy, Derwent specified the DYSS X9-1630C with an automatic board loader. White continues, “We already had an ageing cutting table with a hand loading capability and we wanted to fully automate the loading process on the new machine. AG/CAD delivered the X9 machine with a fully integrated loading solution that can accommodate a stack of boards up to 3.2m by 1.6m, the same size as the maximum cutting area. It can hold upward of 70 sheets of EB doublewall or varying quantities of boards of different thicknesses. As soon as a sheet is loaded and the cutting process started, the auto-loader will pick the next sheet so that it is ready for moving forward once the previous finished sheet is advanced off the front of the machine to be stripped, stacked and packed.”

With 70% of the work flowing through Derwent being production runs from 500 to 3000, the line offers an automated production alternative to traditional die-cutting. The remaining 30% of output is prototypes and smaller runs. For many jobs, the DYSS X9 has now eliminated the need for cutting formes.

Quantifiable benefits

With regard to cutting formes, Derwent Displays has historically ordered around 35 tools every month. By rapidly processing jobs in the 200 to 500 range, the DYSS has reduced the requirement for cutting formes by up to 15 tools per month. This has reduced the cost of externally produced formes by up to £1,500 per month. White says, “Not only have we cut costs with the DYSS, we have been able to reduce lead-times. Completing jobs on the DYSS instead of die cutting has reduced lead-times on many jobs by an average of two days, significantly improving throughput. Equally important is the ability to eliminate the forme cost from small quantity jobs, something that has deterred some customers from placing smaller orders with us. We can now reduce costs on these jobs and make them more viable. We are winning more business as a result. Moving forward, we have hundreds of existing cutting formes in racks and the DYSS will help us to reduce our storage requirement.”

With two cutting machines running side-by-side, Derwent Displays has one operator running both tables. “Not only have we doubled productivity, we still only require one operator to run both machines in this department, effectively incurring no additional labour cost while doubling production,” adds White.

Credit for some of this productivity has to be afforded to the Kasemake CAD software. Derwent designs its projects and creates cut files using the software. These programs are immediately accessible on the DYSS X9, eliminating potential machine downtime.

The Future

“We have only had the DYSS for a short period of time, but we are already realising the benefits. It has lowered costs, reduced lead times and increased productivity. The Combo head gives us the ability to cut all material types and this is opening new doors and bringing us new business opportunities. The flexibility of the cutting head combined with the cost savings and speed of turning around prototypes and small run jobs is generating additional business, particularly in market segments that would have previously been outside our scope,” concludes White.