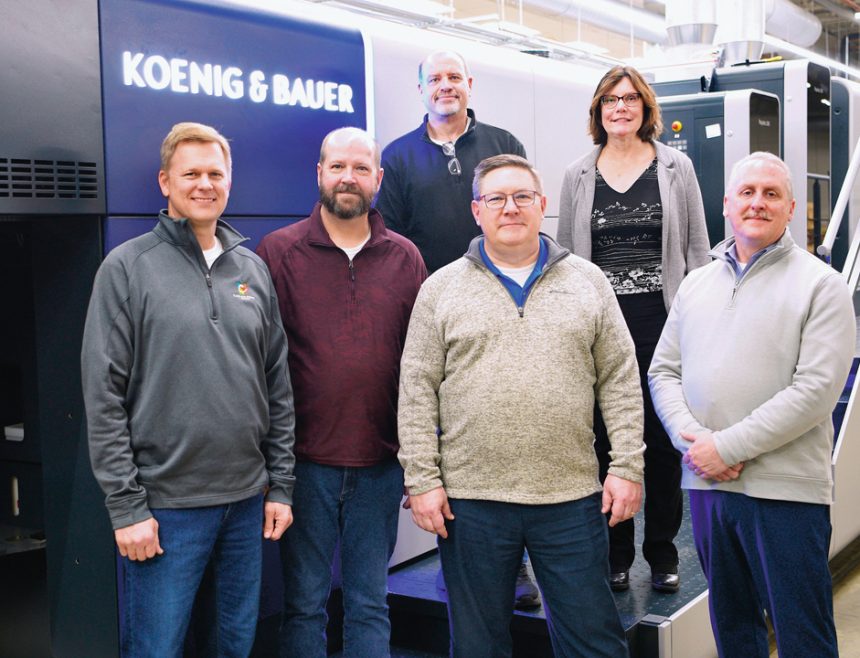

Main image: Jason Sharman, Managing Director of Atlas Packaging, with Fabien Val-Duprez, owner of Cuir CCM.

Atlas Packaging continues to invest heavily in its business infrastructure, following hot on the heels of significant investment over the last few years. After the installation of an EMBA casemaker in 2012 and an Asahi flat bed die-cutter in 2014, the Barnstaple, Devon-based converter has now chosen to extend its converting capabilities, with the addition of £2.5 million high quality flexo post print machine. The new machine was commissioned in September 2016.

“We had a very good final quarter in 2016 and I am glad to say that the momentum has continued early this year as well,” says Jason Sharman, Managing Director. “Thanks to a range of customers in the Horticulture sector, the ramp up to Valentines day always means we are busy during late January and early February and there is then not too long of a gap before the confectionery companies require outer packaging for Easter eggs.”

He continues, “We have always invested in people and systems, especially in our design department. Considering the size of our business, we are very well supported in design, both structurally and graphically — and there is no doubt that this has helped us grow and maintain a solid customer base throughout the south-west of the UK and further afield. But over the last few years, we have tried to adapt too — we very much now see our company as a print service provider; the addition of a new six colour Cuir press has helped us create a niche in the territory.”

Dedicated for high quality

Focusing its attention on higher quality flexo printed packaging, Atlas has created a dedicated print and die-cutting area within its factory. “We decided very early on that we wanted to print offline,” explains Mr Sharman. “To make sure we got the best out of the new press, we also recruited new people to run the machine. Selecting carefully from the litho industry, the learning curve for our new operators was steep but most rewarding.”

The new Cuir press sits alongside two flat bed die-cutters — a Bobst Visioncut and an Asahi AP-1600 Cartonmaster. Once printed and die-cut, the pieces are then glued on a series of speciality multi-point gluers.

“We are delighted that Atlas Packaging has chosen the Mk III press, states Fabien Val-Duprez, Managing Director — and owner — of Cuir CCM. “Having acquired the business from the previous owner almost two years ago, we have been working hard to re-establish Cuir as a leading, reputable supplier of high quality flexo printing machines. This is an important installation for us and acts as an excellent demonstration site for us in Europe. We have been busy, particularly over the last year, with four machines having been sold and installed around Europe.”

Good demo

“We saw a demonstration at an integrated plant in Holland and were impressed with the quality of work it was producing, even though the press was over 10 years old,” explains Mr Sharman. “The operators told us the machine was robust and easy to maintain, something that was important for us as we made our final decision. Our Site Services and Safety Manager, Ray Maze, was really impressed with the simple yet robust design of the machine.”

Mr Sharman concludes, “Cuir has a reputation for building good quality machines that print exceptionally well, but it was still critical to us that we could trust the new owners that they were as committed to the project as we were. We are very happy to be working so closely with Fabien and his team as he rebuilds the company. The build quality of the new press is exceptional and the results coming off the machine speak for themselves. Our customers are impressed with the print registration and outstanding print quality.”