Left to right: Michael Linden (Sales at Bobst Meerbusch), Karsten Hunger and Manfred Janowitz, (Technical Service at Bobst Meerbusch).

Although Bruns Kartonagen GmbH, based in Göttingen in Germany, only employs 25 people, the technical capabilities of its four BOBST folder-gluers and three Bobst flatbed die-cutters allow it to stand out among packaging manufacturers. In 2019, the company further increased its attractiveness in the field of folding-gluing with the addition of a new MASTERFOLD 110 and upgrades to two of its three ALPINA machines.

“One of our customers asked if we could provide him with a video showing the great flexibility and production reliability of our Masterfold 110. This alone demonstrates how much the machine strengthens our market position,” says Karsten Hunger, one of the company’s three Managing Directors. To the same end, Bruns had one of its two Alpina 110 folder-gluers and its Alpina 130 converted to the latest version of Bobst’s MATIC control system, while adding new drive controllers and new motors.

Bruns Kartonagen GmbH was founded in 1946 by Friedrich Bruns as a bookbinding workshop. Nowadays, the company offers its customers a complete range of services from folding carton design and production to delivery right across Germany in its own trucks.

Wide range

Matchboxes, cushion packaging, bottle/glass packages and presentation, six-pack carriers, book slipcases, counter displays and many other types of packaging for customers in numerous industries – the product range at Bruns is extremely broad. Most orders come from industry – including the food and pharmaceutical sectors. But agencies and packaging manufacturers with limited technical capacity also take advantage of Bruns’ abilities.

“We also work as a contract manufacturer in folding-gluing, flatbed die-cutting and laminating – even delivering overnight in exceptional circumstances,” explains Hunger. Above all, the extensive possibilities of the gluing process are in high demand in the market. Customers from all over Germany send pallets to Göttingen with printed sheets or pre-cut blanks to be processed into folded boxes. “Thanks to our new technology, we are able to respond ever-more quickly and flexibly to the demands of the market,” adds Hunger.

Work feels better

The new Masterfold 110 and the upgrades to the Alpina machines have significantly increased working comfort for the machine operators. The setup process has been simplified considerably. Setting up the Masterfold 110 is about 30% quicker for standard boxes and repeat jobs than before. Additionally, when the machine is set up for completely different box variants, Bruns saves 10 minutes on previous setup times. When there are up to ten production changes per shift, the impact is considerable.

The Mastefold 110 is equipped with individual drives. These facilitate the open-frame design of the platforms and allow operators direct access to all machine areas, which, in turn, makes it easier to install special tools and perform maintenance work. The machine’s design also affords a particularly high level of occupational safety. The closed floor areas of the frame platforms minimise the possibility of blank cuts remaining in the machine during job changes, or of there being any mix-ups, as machine operators would see them straightaway. Finally, the individual drives guarantee quiet machine operation – even at high running speeds – and contribute significantly to the machine’s remarkable energy efficiency.

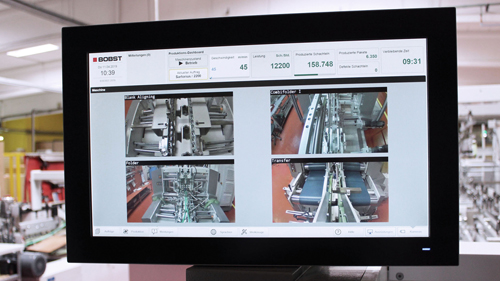

Highlights for the machine operators include central operation via the new HMI user interface (mounted on the feeder) and the Matic control system, which handles all aspects of the machine’s operation. Operators can switch between views at the touch of a button. The Masterfold 110 is equipped with four camera systems to monitor ‘critical’ machine areas.

“We adjust most of the settings and have the entire technology under control via the touchscreen. This saves us a lot of running about,” was how one machine operator described the main advantage of this central operation. “If, for example, the ACCUEJECT eliminates glued boxes incorrectly, we can see the reason from here.”

The causes of any technical problems in the machine can usually be located quickly via the touch monitor. “Particularly in contract manufacturing, it is important to be able to guarantee customers the highest level of production reliability,” explains Hunger. “The Masterfold 110 makes this a lot easier for us.”

Many automated steps

Depending on the type of folding carton, manual work during job changes is largely reduced to replacing and adjusting tools. Easy access to all machine parts, centralised operation and automatic settings thanks to the Matic control system – all these features contribute to the short setup times.

Tools are compatible with all four folder-gluers, meaning they can be used on both the Masterfold 110 and the three Alpinas. The ease of operation has also been significantly increased on two of these machines by their upgrade to the latest version of the Matic control system. Its intuitive menu navigation is almost identical to that of the Masterfold 110, so operators can work on all machines without problem. Originally, the third Alpina was due to be sold, instead it has been kept in operation as a back-up and for peak periods.

Total support

“Bobst provided us with faultless support during project planning and commissioning,” said Hunger. Bruns is using Bobst’s remote maintenance service, Helpline Plus. In order to be able to use machine data for process optimisation in the future, Bobst’s three flatbed die-cutters and folder-gluers are to be linked to the supplier’s ‘Connected Services’. This will allow for an even fuller overview of production and access to data while on the road – for example, to check whether orders can be realised in the event of customer requests at short notice.