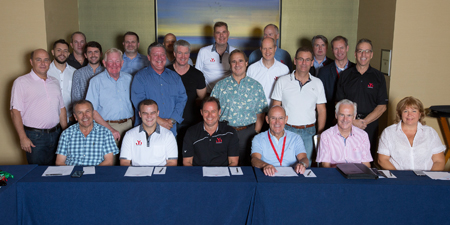

JB Machinery used SuperCorrExpo 2016 in Orlando, Florida as an opportunity to bring together their sales representatives from around the world for their second Global Sales and Technology Meeting. During the afternoon event, the group which included delegates from Europe, the United Kingdom, Asia, Russia, South and Central America, South Africa, Australia, North America and Canada discussed JB applications and the latest market trends, and were brought up to speed on the introduction of four new JB Machinery products for flexographic printing corrugated.

The new products JB introduced during SuperCorrExpo included:

- ColorDry™ XL3000 IR drying system which offers the latest technology in IR drying safety and improved performance, including Sentinel™ with Trident technology and power drop down for ease of maintenance and access.

- InKomand®, JB’s ink temperature control system minimizes the need for the addition of chemical additives, thereby reducing overall operating costs. Additionally temperature control provides improved ink drying, faster set-ups and a reduction in time spent on wash-ups.

- KleenPlate® 2.0 the latest version of the award winning KleenPlate product line that eliminates the need to stop to wash plates during production. The new product incorporates even more simplicity, full automation, greater efficiency and versatility than the original 2012 Innovator Technology winner.

- KomandCenter™, a system which brings all of the JB controls together in a single user interface for efficiency, total process control, ease of use and comprehensive reporting.

On hand to discuss and answer questions about the products, as well as the existing line of JB products, were executives and technical experts from JB Machinery and XDS (JB’s Engineering and Manufacturing Division).