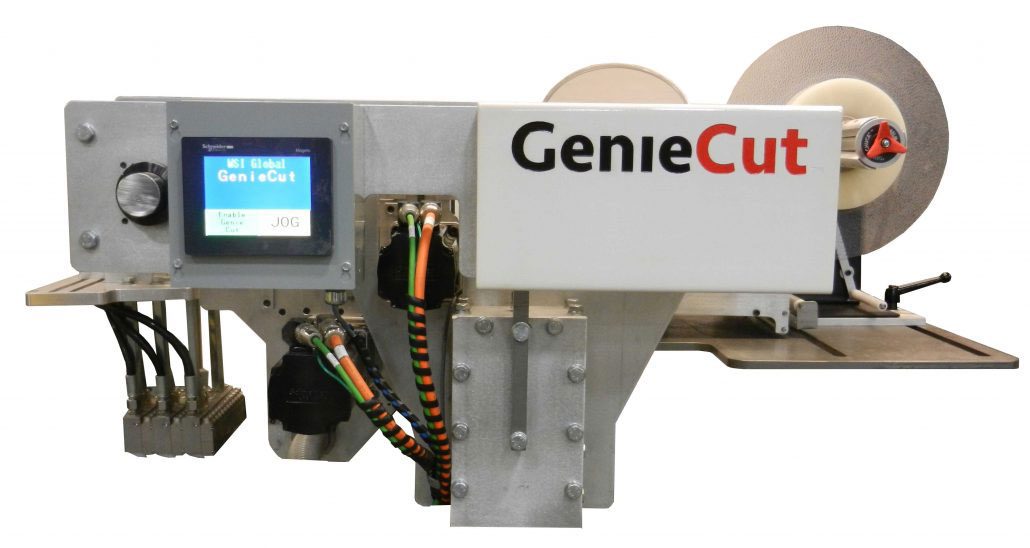

WSI Global, a leading manufacturer of finishing equipment for the carton converting, liquid packaging, and corrugated industries, announced the release of the GenieCut windowing machine. Designed to incorporate the action of a windowing machine directly into a folder-gluer line, the Genie Cut delivers increased ease of use and drastically reduced makeready times. It is capable of operation at speeds of over 600 belt feet per minute, and is ideally designed for carton converting applications in the food and cosmetics industries.

The GenieCut detects each printed, diecut carton being fed from the host machine and uses highly accurate sensor technology to place a designated length of film at a precise location on the carton. Critical in windowing applications, the GenieCut is capable of reliably forming a complete, solid frame of glue around the entirety of a carton window opening.

The machine can save and recall job setups for different carton windowing processes, reducing makeready time between jobs and simplifying training and operation. It also does not contact the paper with the glue applicator, leading to reduced cleaning and maintenance needs. With fewer moving parts and reduced maintenance needs, it is simpler to operate and is capable of processing cartons more quickly. For more information, visit wsiglobal.com/genic-cut/