The board of BillerudKorsnäs has now made the decision to carry out the largest investment in the history of the company and one of the largest in Sweden in recent years – the investment in a new board machine at its Gruvön site. The decision has been made in view of growing demand for sustainable packaging solutions for food and beverages globally.

The investment of SEK 5.7 billion includes the construction of a new board machine at the Gruvön production site and rebuilds in the existing pulp mill. The board machine will have an annual capacity of 550,000 tonnes of board, making it one of the largest of its kind in the world. The machine will produce liquid packaging board, cartonboard, food service board and liner. The investment project will start immediately and production is expected to start in the first quarter of 2019.

The mill as it is today

“This is a historical decision for BillerudKorsnäs. The stable market growth in liquid packaging board and other cartonboards, together with our unique expertise in this area, mean that we are perfectly positioned to satisfy global demand. Access to renewable raw materials from sustainably managed forests in the Nordic region was a key factor when evaluating different alternatives,” says Per Lindberg, President and CEO of BillerudKorsnäs.

Smart packaging solutions can reduce dependence on fossil fuels, reduce climate impact and littering, and also increase food safety. Demand for sustainable solutions is growing around the world as increasing numbers of brand owners, food retailers and consumers make conscious choices. As current capacity at BillerudKorsnäs’ production units is not sufficient to meet future demand, the opportunity of new board production at Gruvön has been investigated in detail since 2015.

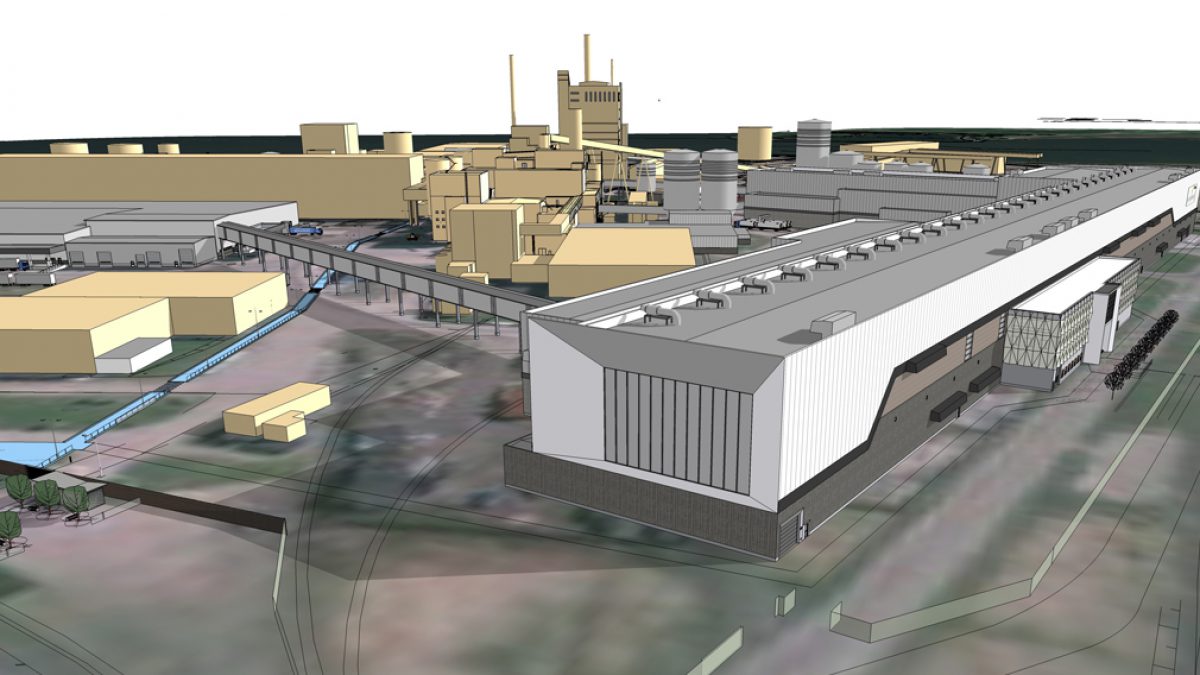

How it will look when finished

In addition to growth in liquid packaging board and other cartonboards, this decision will result in a streamlining of the production structure within the company. Current paper production at Gruvön will gradually be transferred to other plants within the company during ramp up of the new board machine, with the aim of offering customers fully satisfactory alternatives. Gruvön’s production of high quality fluting will not be affected by the investment.