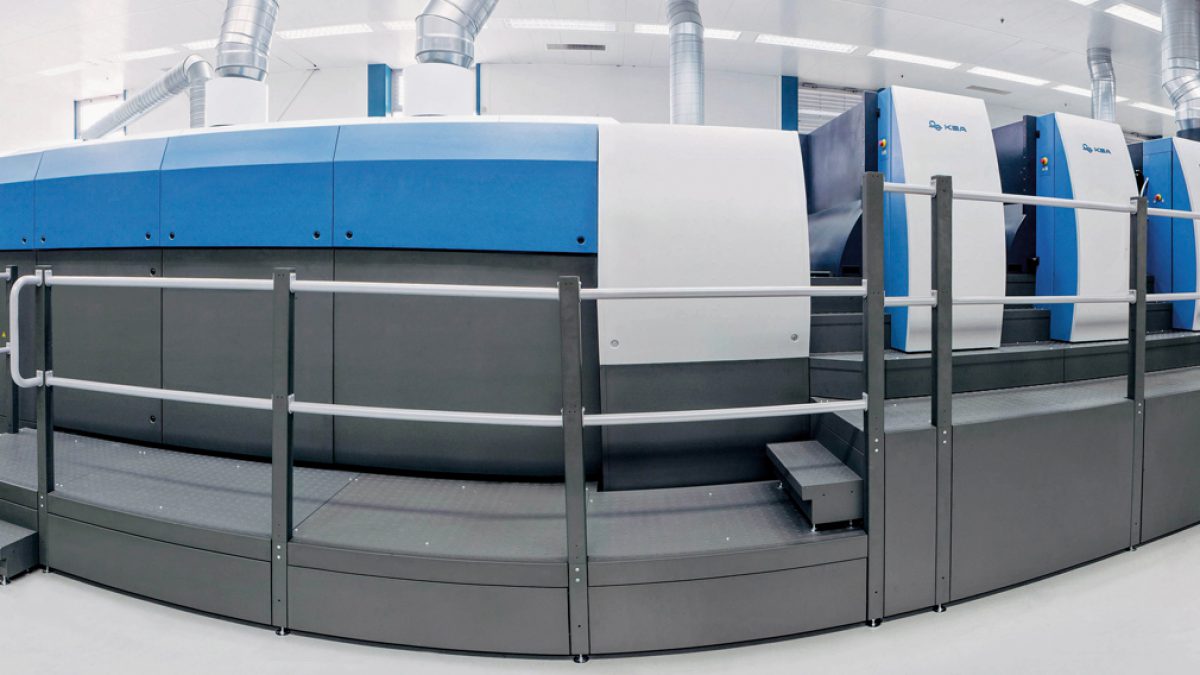

Kent based, high quality carton and greeting card printer Offset Print and Packaging Ltd have purchased their 4th KBA press; a Rapida 106 six colour with coating. The new press, which will be installed in summer 2017 will join their existing Rapida 142 and allow them to offer their customers the opportunity for both B1 and large format carton production in one location. This range of formats is a great offering from an independent UK packaging company and has allowed Offset Printing and Packaging to maintain a loyal customer base.

Offset Print and Packaging (originally known as Offset Productions and Technical Services) was established in 1971 by Chairman, Hugh Jarvis and his father, Maurice, on the site of a former water works in Maidstone. The business now employs 70 people at its state of the art 93,000 square foot manufacturing facility in Aylesford, Kent where they offer design, manufacturing, warehousing and account management services to customers across the UK and Europe. Day to day operations are taken care of by Managing Director of Operations Vince Brearey and Managing Director of Sales Edward Bone. The business has always had an enviable reputation for quality and customer service.

Speaking about their decision to re-invest in KBA Rapida technology Vince Brearey states, “This is the fourth KBA we have purchased, our business has been built on this technology which has allowed us maintain our customer base and grow even further.” He continues, “We have researched the potential of adding a highly specified machine which would allow us to take out two of our existing presses. With the equipment we have specified on the new press we will be able to make ready extremely quickly, with minimal waste and comfortably match the performance of the outgoing presses.”

High Productivity

The new press will provide the highest levels of productivity with a top speed of 18,000 SPH and simultaneous plate changing technology (SPC) which allows all the plates to be changed in 50 seconds whilst other washing activities take place. The press is also equipped with KBA’s sensoric infeed system (SIS) and roller declutching which are standard items on the 106 Rapida range.

Ultimate Flexibility

More efficient production on a broad range of substrates is possible with the new press as it is equipped with both a CX package and a plastics package; this will allow printing of a great variety of materials of up to 1.2mm thick. The press is being supplied with capability for production with both conventional and U.V. inks and coatings, and is equipped with a water cooling facility which greatly reduces heat in the press hall and reduces wear and tear on the peripheral components.

Colour – Controlled

For colour control at the highest speeds with the lowest waste count on every make ready, the press is equipped with QualiTronic ColorControl; KBA’s inline colour measurement system, alongside the Ergotronic Colour control desk for standardised print quality analysis and reporting.

The performance data of the press will be automatically captured for analysis via KBA’s LogoTronic Professional which will provide detailed reports on every activity taking place on the press. This system also provides the link to pre-press, an MIS system and allows the storage of the colour quality data produced by the press via KBA’s Qualitronic QualityPass and QualiTronic ColorView.

Mr Brearey states, “Most customers would now want us to guarantee that we have all the relevant reporting methods to ensure that what comes out of the press is at the desired level of quality. Colour consistency and its reporting are extremely important for our clients and will certainly play a part in attracting new ones. To have a tool like QualiTronic Colour Control alongside Quality Pass for I.S.O. 12647-2 and ColorView will provide them with even greater reassurance of our ability to match and maintain colour to very tight tolerances throughout a press run.”

KBA (UK) Ltd. Sales Director Chris Scully added, “We have had a long and successful association with Offset Printing and Packaging in mid and large format presses. However, we never take anything for granted. We are absolutely delighted that they have chosen to return to KBA for their latest investment. They have added a highly specified, highly productive machine to work alongside their existing large format press. This has to be one of the broadest offerings of all the independent packaging companies in the UK.”