Digital printing is not just a passing phase – it’s here to stay. As all things become digital along with changing consumer behaviours driving brands towards shorter runs, more SKUs, shorter lead times and faster time-to-market, many converters know they need to act now to get into the game. Here are 10 points to consider when planning your first steps into digitally printed folding cartons.

• Quality and colour – in today’s digital print world, matching the quality of offset CMYK is pretty much a given. In the folding carton space, reproducing brand colours are a more complicated story. Brands expect converters to match these colours across all the printing platforms used to produce their cartons. Be sure to consider how well the digital print technology can match the colour and quality of your offset press, so that the move to digital will be as seamless as possible for your customers.

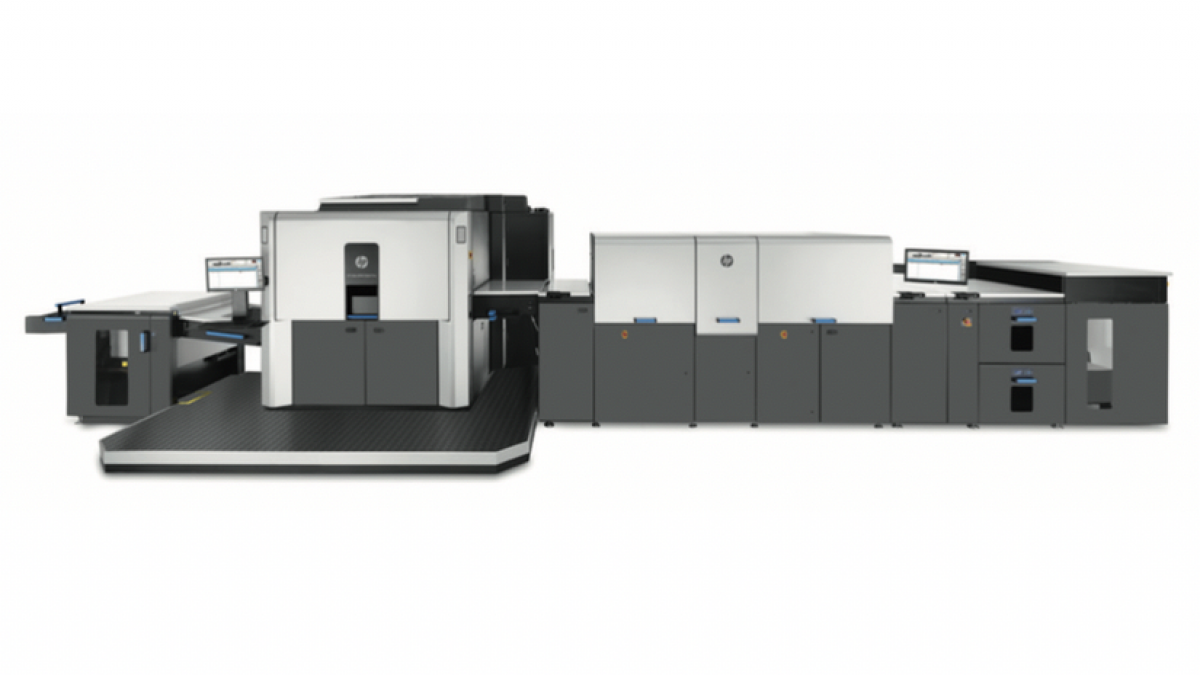

• Quick make-ready – digital print eliminates the time-consuming setup and complexity in preparing a job for print production. Make sure your new press comes with the right tools and features to minimise make-ready and waste by automating and optimising tasks.• Maximum jobs per day – with more and more short runs landing at your doorstep, make sure you choose a digital printing solution that can complete dozens of jobs per shift. Consider a solution that has a multi-feed system for quick changeover between substrates, automatic features to zero down your makeready and the right workflow to maximise the number of jobs per shift.

• Substrate range – to win more accounts and say ‘yes’ to more customers, be sure to have an answer to the diverse packaging requirements of your customers. Make sure you can print not only on all board grades including SBS and FBB, but also on Kraft, recycled , metalised (met-PET) and even plastic substrates. Some digital technologies are more adept at handling diverse substrate types and allow equally perfect results on any type of substrate.

• Custom ink colours – some spot and Pantone colours may be out of the digital colour gamut even when using extended gamut inks like Orange, Violet and Green. Rhodamine red is a common example. Make sure you can order custom ink colours through your digital press manufacturer, so you can use them with your digital press as separate spot inks whenever needed.

• Brand protection – as you respond to brands’ increasing demand to win the battle against counterfeiting and diversion, make sure you can offer next generation solutions with several layers of brand protection for your customers. A digital printing technology that can print covert serialisation using invisible inks and/or micro-text directly on the press gives you the ability to offer high-margin, added value solutions.

• Opaque white – using opaque white inks with offset printing can be a time-consuming task and often requires multiple stations or double runs. With digital print, that pain point can be easily addressed. Make sure your digital press delivers high quality, high opacity white ink that you can easily set up for single or multiple hits to control varying opacity levels.

• Workflow – many converters already use workflow tools such as Esko Automation Engine, which automates pre-press tasks for both offset and digital. Make sure your digital press can easily be integrated into your existing workflow processes and allows maximum balance between the various presses in your site.

• Choose a partner – transitioning to digital inevitably involves some degree of a learning curve. Make sure your chosen vendor can walk you through the learning path and provide you with training, not only to operate the press and integrate workflow but to also build the business acumen you need to succeed. How deeply are they engaged with their customers, brands, partners, and the market as a whole? Don’t just choose the lowest priced vendor. Choose a partner whose success depends on your success.

• Future proof – there are several digital print technologies entering the folding carton market. Each has its own strengths and weaknesses, but ask yourself whether the specific vendor has a technology that’s been proven in the field, over the test of time. Are the brands embracing them and are converters reaping profits? Make sure the technology you choose has a bright future ahead – one that constantly evolves and pushes the envelope with a heritage of long-term success.