In July 2019, a new six-colour Rapida 105 PRO with coating and UV capabilities went into production at Grafičar d.d. Ludbreg in Croatia. This installation has secured an important competitive edge for the company in the packaging market — and at the same time opens the door to expansion into further market segments and offering interesting export opportunities.

The Grafičar group employs over 450 people and is a leading packaging producer in Croatia. With a diverse product portfolio, ranging from folding cartons and labels, to varied types to bags and sacks for fillings from 0.5 to 50 kg, it has established itself as a competent partner in all matters relating to packaging production.

Broad spectrum of substrates

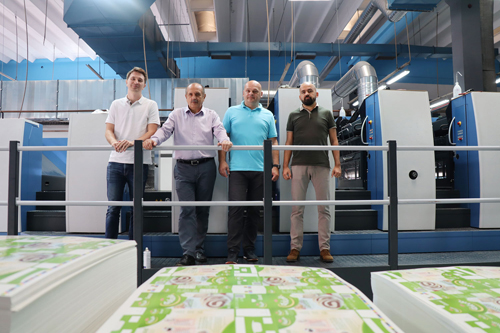

To cater for this wide range of products and the ensuing diversity of paper, board and film substrates, Grafičar uses both offset and flexo printing processes. “It is this combination which makes the difference and places us in a strong position in the Croatian market,” says Director Franjo Beser, who manages the company together with his sons Siniša (Sales Director), Dalibor (Technical Director) and Ivan (Head of R&D).

Dalibor Beser explains the background to the investment decision. “We are seeing increasing performance demands on offset printers when it comes to speeds, quality and production reliability, and that made it simply necessary to purchase a modern press.”

Offset printing technology from Koenig & Bauer has already played an important role in expansion plans at Grafičar in the past. “The Rapida 104 is one of the kingpins of our press room and that naturally gave Koenig & Bauer a certain initial advantage over other manufacturers,” says Ivan Beser. “The service and support offered by Koenig & Bauer, with local service technicians to ensure smooth commissioning and training and to safeguard the availability of the press in three-shift operation, was an equally decisive factor.” Any minor issues can already be solved in advance via the remote maintenance module PressSupport24.

Left to right: Ivan Beser, Franjo Beser, Siniša Beser and Dalibor Beser.

Quick plate change

In response to the growing demand for high-quality finishing, Grafičar configured its six-colour press with an inline coating tower. Thanks to the fully automatic FAPC plate changing systems, all six plates can be changed within just two minutes, which is also sufficient for simple makeready on the coater. Further important contributions to makeready savings are derived from the DriveTronic technology. All format and air settings for the full spectrum of substrates used by Grafičar are in the meantime stored on the ErgoTronic console. That accelerates job changeover significantly and makes work so much easier for the press operators.

CleanTronic Multi washing systems, with their separate solvent circuits for use with conventional and UV inks, simplify switching between the two processes and provide for cost-effective hybrid production on the Rapida 105 PRO. “The high level of automation has boosted our productivity significantly and enables us to compensate the market trend towards ever shorter runs,” says Dalibor Beser.

Colour stability

It is one thing to attain high quality at a given moment, but quite a different matter to maintain this quality over time. Accordingly, Grafičar has deliberately configured the Rapida 105 PRO with a number of cutting-edge quality control modules. Inline colour control is handled by QualiTronic ColorControl. A 4K camera system installed after the coater automatically scans a colour bar to determine the optical densities. If any deviations are detected, countermeasures are initiated to achieve the maximum possible colour stability over the entire length of a run. This quality monitoring and control system has been expanded further with the option QualiTronic PDFCheck, which adds two additional quality functions: Sheet inspection and comparison with a pre-press PDF.

“Especially in packaging printing, this form of quality control is important and that is all the more true when you are working in pharmaceutical packaging. The system spots flaws in even the smallest font sizes,” says Ivan Beser.

Each sheet is numbered by the Sheet Ident inkjet system already before it enters the press. With the error report generated by the quality control system, it is then a simple matter to localise any imperfect sheets in the pile and to remove them before further processing.

The future now

“With the installation of the Rapida 105 PRO, we have taken a giant step forward and can now offer our customers even better service in terms of quality, reliability and availability. At the same time, the Rapida 105 PRO helps us to further develop our product portfolio and opens up additional opportunities in export business,” concludes Franjo Beser.