Impack has once again taken up a new challenge by offering better ergonomics and productivity at the Model Obaly a.s. plant in Hostinné in the Czech Republic. The Hostinné plant belongs to the Model Group, which has been developing high-quality packaging and display solutions in solid and corrugated board for more than 135 years. Active in many European countries, the group has a structure oriented towards the fast and error-free processing of customer orders.

Machine performance analysis

As François Granger, Impack’s Technical Representative, testifies, from the first visit to the factory in Hostinné, Impack already had an idea of the solutions to be provided to meet the company’s needs and shortcomings.

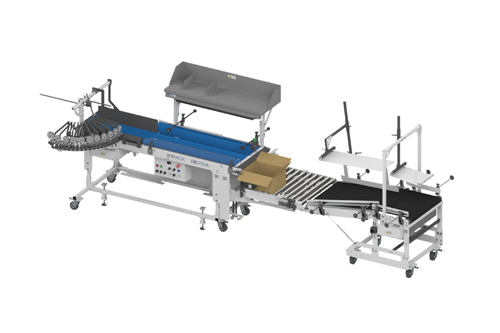

Faced with the great complexity of today’s packaging market, Impack offers a high level of analytical capacity and industry know-how in its solutions. After evaluating the equipment and folder-gluer performance and following Impack’s recommendations, Model Obaly opted for the universal packing machine — Ergosa A — in order to optimise the functions of its operators while maintaining increased productivity.

Faster packing

The Ergosa A is a compatible packer for solid and corrugated board. It adapts to any limited space while offering a great improvement in terms of ergonomics and packing speed. The packer processes different types of products at high speed, while minimising physical constraints for employees. This solution therefore combines productivity and security.

The universal packers of the Ergosa series combine the flexibility of a semi-automatic packer with the performance of an automatic packer. Packing speeds can exceed 100,000 boxes per hour.

Beneficial improvements

Among the main improvements already seen, Petr Etrich, Operations Manager at the Hostinné plant, highlights the fact that operator movements have been reduced. “Only one employee is working on the Ergosa to pack the same folder-gluer speed where there used to be two employees.”

The packing efficiency per employee was therefore doubled. Thanks to the reduction of one man at the end of the folder gluer, the entire packing process has become more economical.

Continuing collaboration

According to the plant operators, “Impack’s solution is simple and intelligent. The machine adjustment is easy and quick.” The employees seem to have a positive opinion of the use of the machine and they have been trained to master the production tool perfectly in harmony with the folder-gluers.

“Today, the cooperation between the two companies is at an excellent level,” says François Granger. “Model Obaly is eager to look at future projects and apply new Impack solutions in their production lines.”

“This major partner has now become a reference customer,” concludes Stefan Badertscher, Director of Sales and Marketing at Impack Packaging. “As experts in the design of equipment for folding and gluing lines, our presence in Europe continues to grow. Indeed, future projects are beginning to emerge within Model Group, particularly in Germany. Recently, we visited the factory in Opava in Czech Republic and potential projects for other packer solutions are being considered already.”