Komori Corporation has confirmed the opening of the newly upgraded Komori Graphic Technology Center (KGC) Smart Factory at its Tsukuba Plant. This renewal marks the third phase of renovations, aligning with Komori’s commitment to developing cutting-edge printing solutions and promoting sustainable practices within the industry.

The newly unveiled KGC Smart Factory is designed to address the growing demands for efficiency in today’s printing landscape. As the industry faces increasing pressure to manage smaller print lots, shorter turnaround times, and rising material and energy costs, the KGC Smart Factory represents a pivotal leap towards automation and higher productivity.

“The transformation of KGC into a fully integrated smart factory underscores our dedication to helping print service providers not just survive but thrive in a rapidly evolving market,” said Lance Martin, Vice President of Product Marketing, Komori America. “By leveraging cutting-edge automation and connected workflows, the KGC Smart Factory demonstrates what’s possible when technology and teamwork come together for the benefit of our industry.”

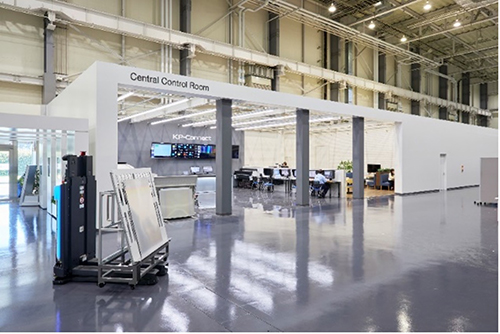

At the core of the KGC Smart Factory is a newly installed central control room that monitors all aspects of the print production workflow in real-time. The heart of this system is Komori’s KP-Connect Pro, a sophisticated Manufacturing Execution System (MES) that connects and tracks every stage of production—from prepress to postpress—enabling factory managers to oversee and control the entire operation with unprecedented precision.

Additionally, the KP-Connect Alliance Program, launched in 2016, continues to expand. It connects all print-related workflows across different technologies, fostering collaborative innovation between Komori and its alliance partners.

Komori’s Connected Automation concept integrates all stages of production, from prepress, printing, postpress, to quality inspection and logistics. The automation of printing processes is not achieved by Komori alone but in collaboration with partner companies. With the involvement of advanced CTP sorting equipment and Autonomous Mobile Robots (AMR) to transport printing plates, the factory achieves unprecedented levels of workflow automation.

Alongside the technological advancements, the KGC Printing College continues to provide educational resources, offering hands-on training, seminars, and expanded curriculum focused on the operations of smart factories.

In its new role, the KGC Smart Factory will serve as an open innovation hub, where Komori, printing companies, and alliance partners can work together to push the boundaries of print technology. By combining human expertise with the latest in printing automation, the KGC Smart Factory aims to improve productivity, profitability, and sustainability across the global printing industry.